About Silver Conductive Ink on Non-Tactile Membrane Switches

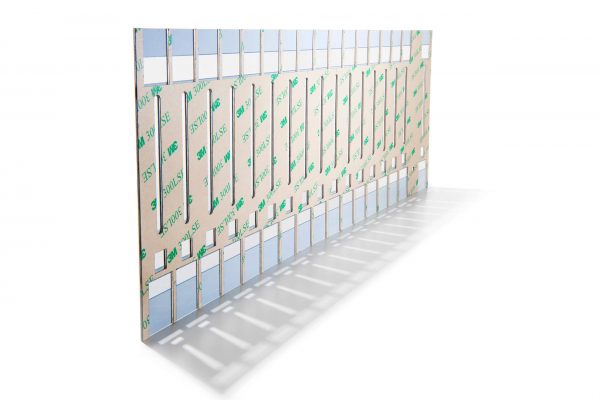

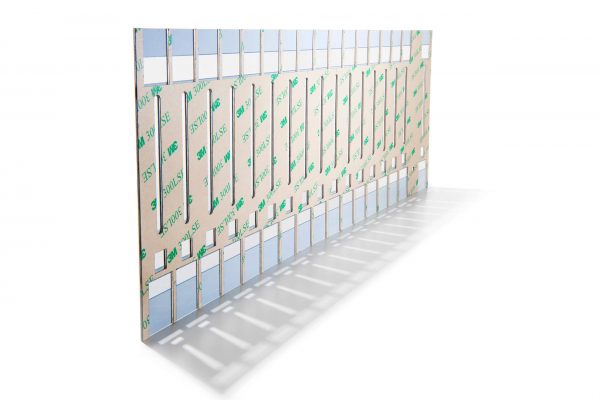

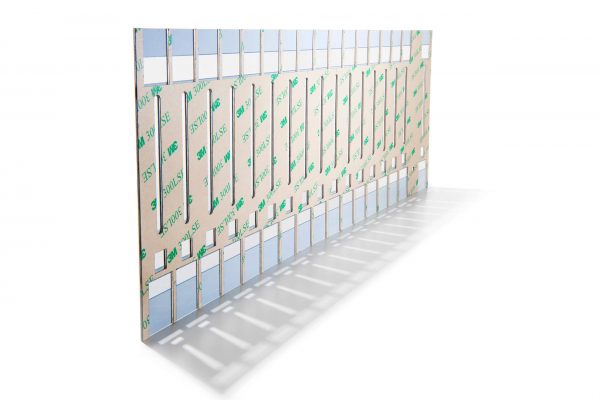

This three-layer switch, comprised of a graphic overlay, a circuit spacer, and a screen-printed silver ink circuit, is the simplest type of membrane switch. Because they tend to be the least expensive option, they are often implemented as a cost-cutting measure in the overall design. However, because there is no tactile feel when these circuits are actuated, there is often a sound or light component put it place to indicate activation. Depending on the device and the design, electronic shielding techniques may also need to be incorporated.

Advantages

- Smaller Number of Components

- Affordability

- Long Lifespan (up to 1 million actuations)

Disadvantages

- Less Trace Precision (1 mm minimum pitch)

- Less Design Flexibility

- No Tactile Feedback

Graphic Overlay

The overlay is the top layer of a membrane switch and is the interface between you and the machine. The overlay creates the look and feel for your product. Graphic overlays can be made of polycarbonate, polyester or acrylic materials in various gloss levels, textures, pencil hardness and gages to meet your needs.

Two of the most important issues to consider with graphic overlays are durability and environmental concerns. It is essential to choose a material that will outlive your application requirements. Polycarbonate offers more flexibility with regard to design and processing. However, polyester is more durable due to its dimensionally stable properties.

Circuit Spacer

Non-tactile membrane switches can be designed with a wide range of actuation forces. The actuation force is determined by the circuit spacer thickness. The thicker the spacer, the more actuation force is required. Conversely, the thinner the spacer, the less the actuation force. If required, a non-tactile membrane switch can be designed as thin as .021”.

Adhesives

Surface contact is fundamental to adhesive performance. The strength of the bond is determined by the surface energy. High surface energy materials (like an un-waxed car) are very easy to adhere to. For low surface energy materials (which are more like a highly waxed car), special adhesives with flow agents are typically required to enhance both the initial bond and the long-term hold.

Other factors to consider when selecting an adhesive technique include whether the surface is textured or smooth, flat or curved, and painted or unfinished.

Silver PET

The circuity in this simplest of membrane switches typically consists of conductive silver screen-printed onto an underlying flexible surface, such as polyester. This approach is very simple, which makes it easier to design and produce, and therefore less expensive than copper flex or PCBA circuit layers.

When printed on .005 polyester, conductive silver ink’s resistance range is <10 ohms to 100 ohms with a rating of 30 volts DC. These electrical properties are a key factor when determining whether screen-printed silver will be suitable for your specific project since silver-printed circuits are for low-voltage applications only.

Different conductive and dielectric inks are available to help engineers specify and manage these electrical properties more precisely.

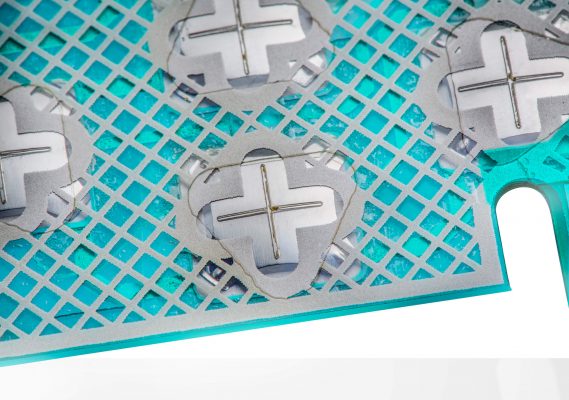

Shielding

A good membrane switch manufacturer can recommend and design the proper shielding to meet your ESD, EMI, or RFI requirements.

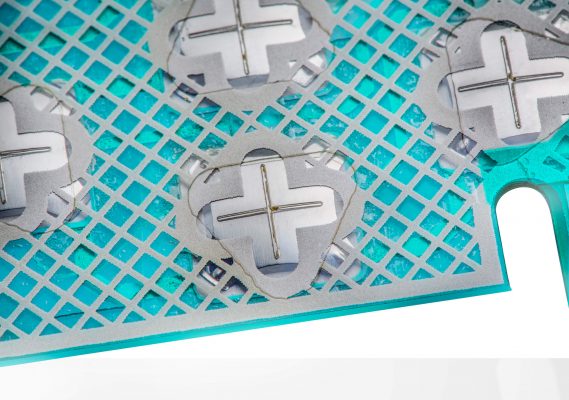

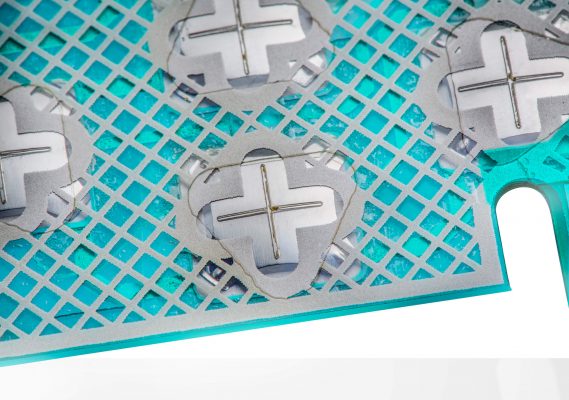

Most use two methods for shielding membrane switches: 1) copper or aluminum foil with or without laminated polyester to the second surface, or 2) screen printed conductive silver ink in a grid or complete coating on the first surface.

There are three common methods for grounding shields: 1) a tab can be attached to a stud or standoff on the metal backer or the metal enclosure, 2) the shield can be terminated into the pins of the membrane switch tail, or 3) the shield layer is wrapped around the membrane switch and ground to the enclosure.