Our state-of-the-art cutting processes feature an optical registration system that enables precision print-to-cut registration when producing printed graphic products, and perfect cut-to-tape alignment of a variety of components.

Our state-of-the-art cutting processes feature an optical registration system that enables precision print-to-cut registration when producing printed graphic products, and perfect cut-to-tape alignment of a variety of components.

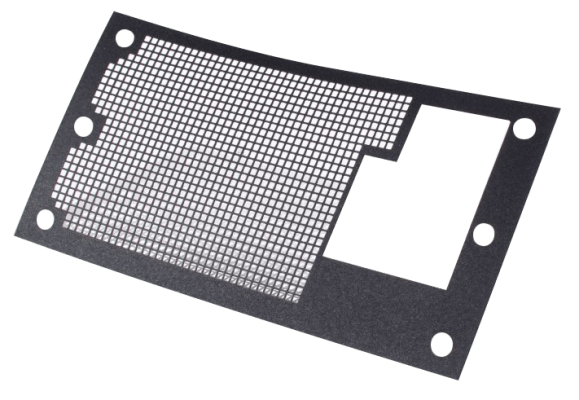

Examples of precision cut components:

- Graphic Overlays

- Membrane Switches

- Gaskets

- Lenses

- Adhesive Assemblies

FAST PROTOTYPE TURNAROUND

If we have your material on-hand, we can get samples cut within just a few days, allowing you to quickly prove out form fit and function.

Types of Cutting

Die Cutting

Flash Cutting

Flash cutting is ideal for prototyping (short runs), or projects where flexibility and rapid or frequent changes may occur. The process is also ideal for fast-turnaround requirements. Flash cutting utilizes computer-controlled laser and precision Zund blade cutting machines that product extremely accurate dimensional cuts in a variety of materials.

Kiss Cutting

At Kiss cutting is a precision cutting process in which the cut is through the primary material, but doesn’t penetrate the adhesive or backing liner. This allows for a larger backing/liner that remains after the cut, which is easier to remove in the manufacturing process.

Cutting Equipment

Flat-Bed/Clam Shell Die Cutting

Cut types: die cutting, kiss cutting

These tried-and-true machines are the backbone of any die cutting business. We rely on them for a significant amount of our precision cutting needs. They work like a high-tech cookie cutting, stamping our precise part shapes from a wide range of materials. They work fast, extremely efficiently, and are ideal for any large-run project.

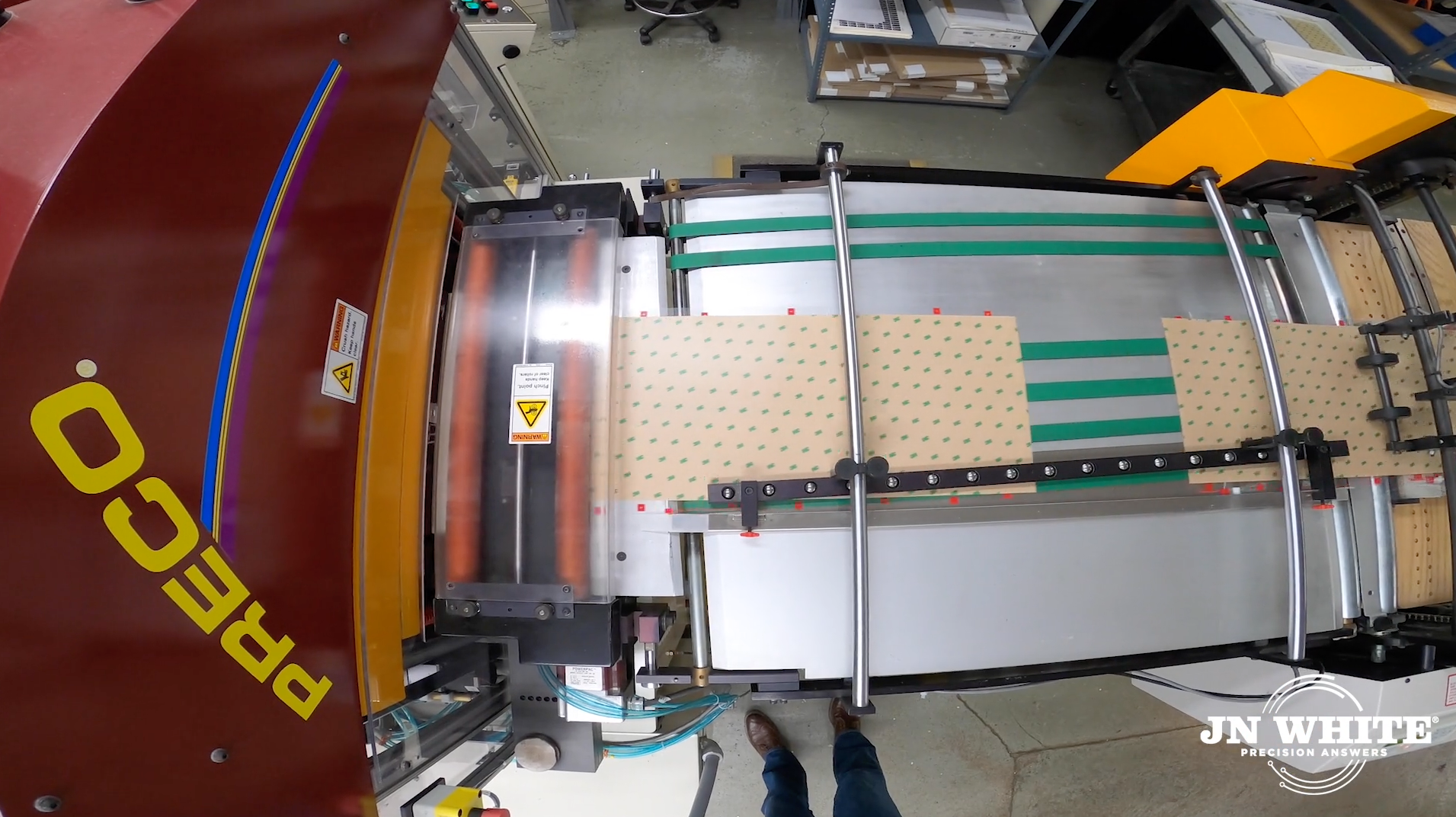

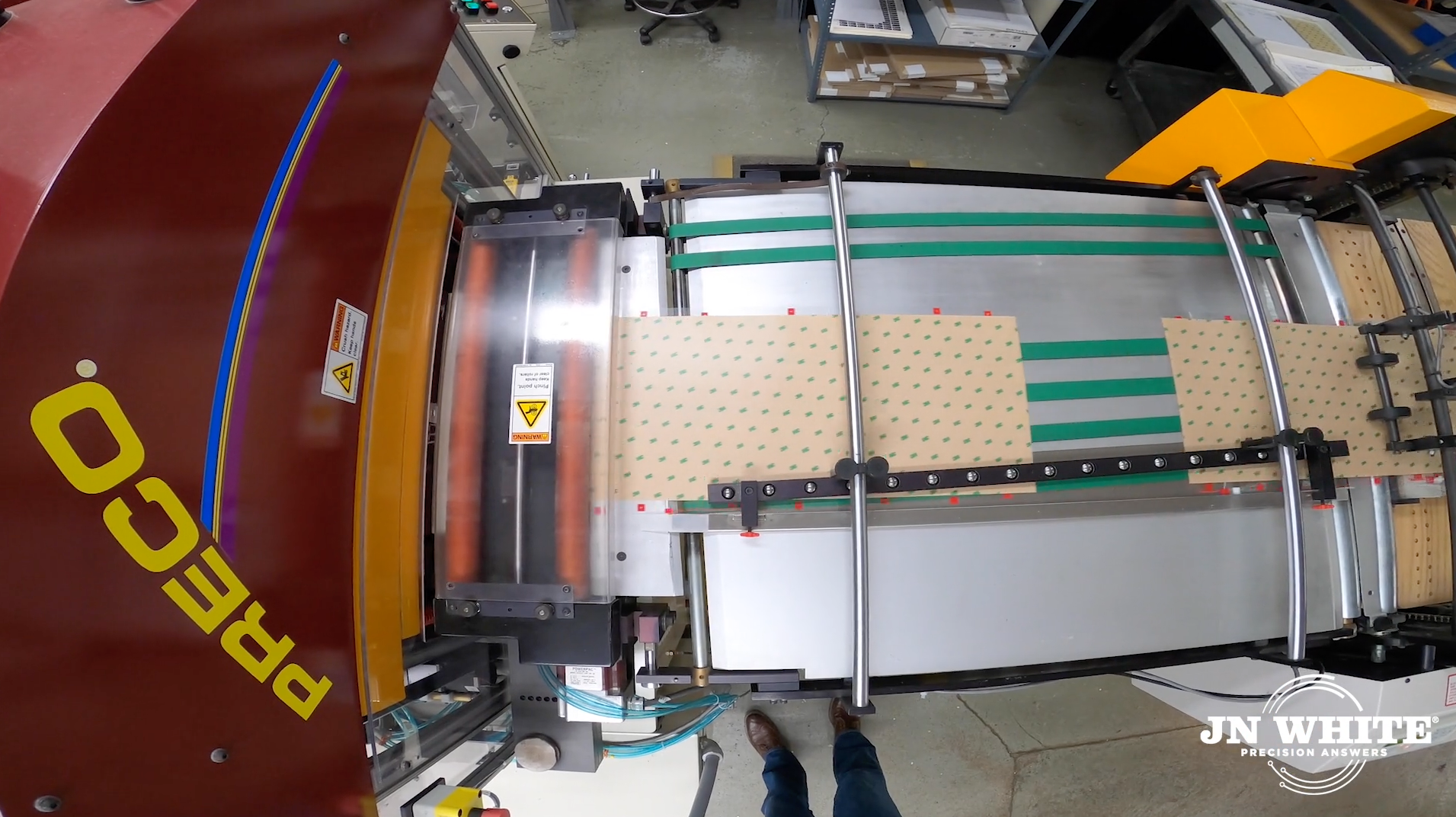

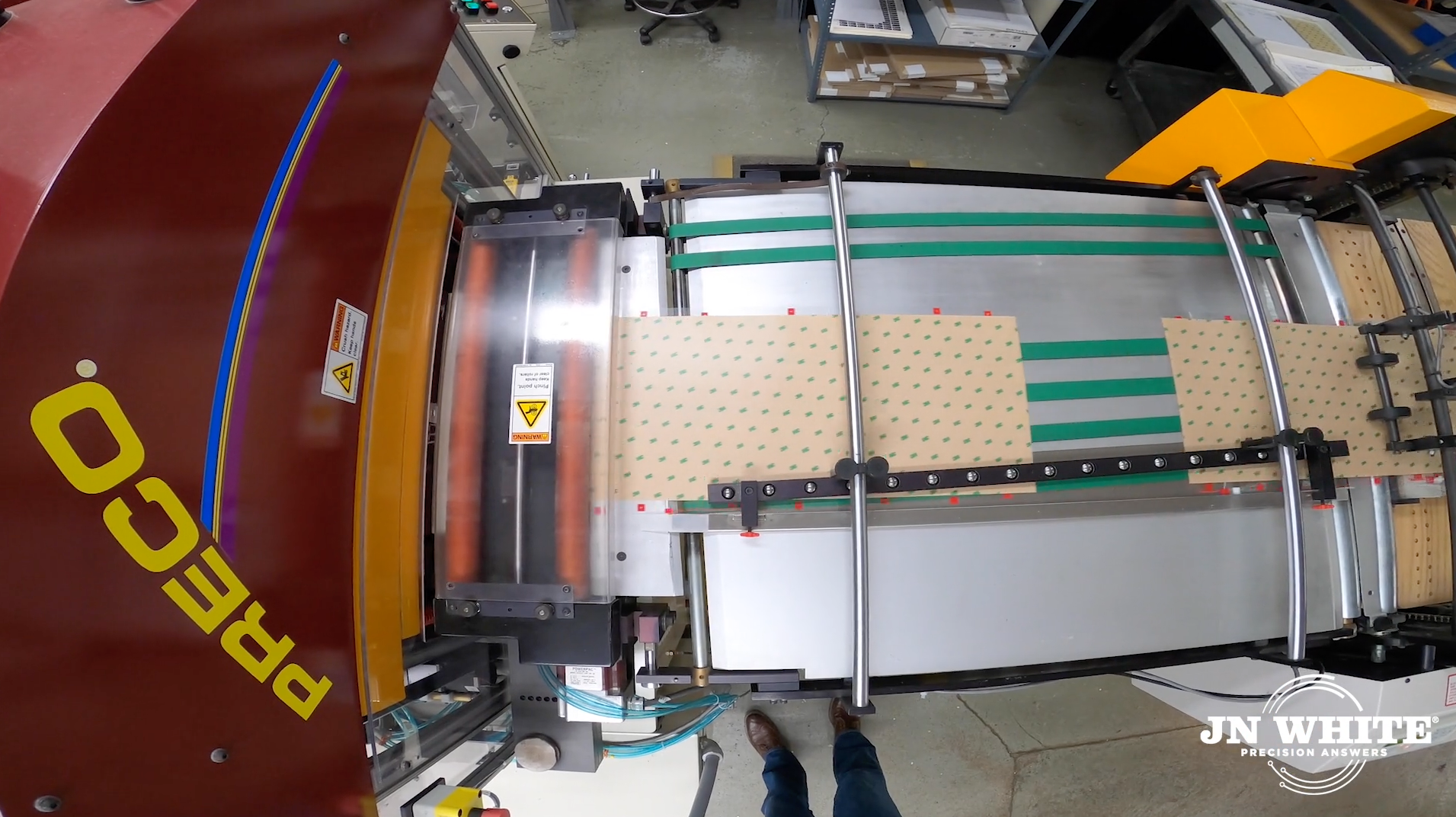

Preco Automated Die Cutting

Cut types: die cutting, kiss cutting

Our Preco automated die cutters use video optical registration systems to assure that the finished “print to cut” allignment is right every time. The camera system locates targets that have been printed on the press sheets and adjusts the strike of the die to those targets. If the printing moves on the sheet so does the cutting. This process also allows us to purchase fewer cavities in a tool. With the camera registration system the press will “step through” the sheets with exacting precision. As an example It is very common for us to use a 5-up Preco tool for a 20 up printed sheet saving our customers money on their initial tooling charges.

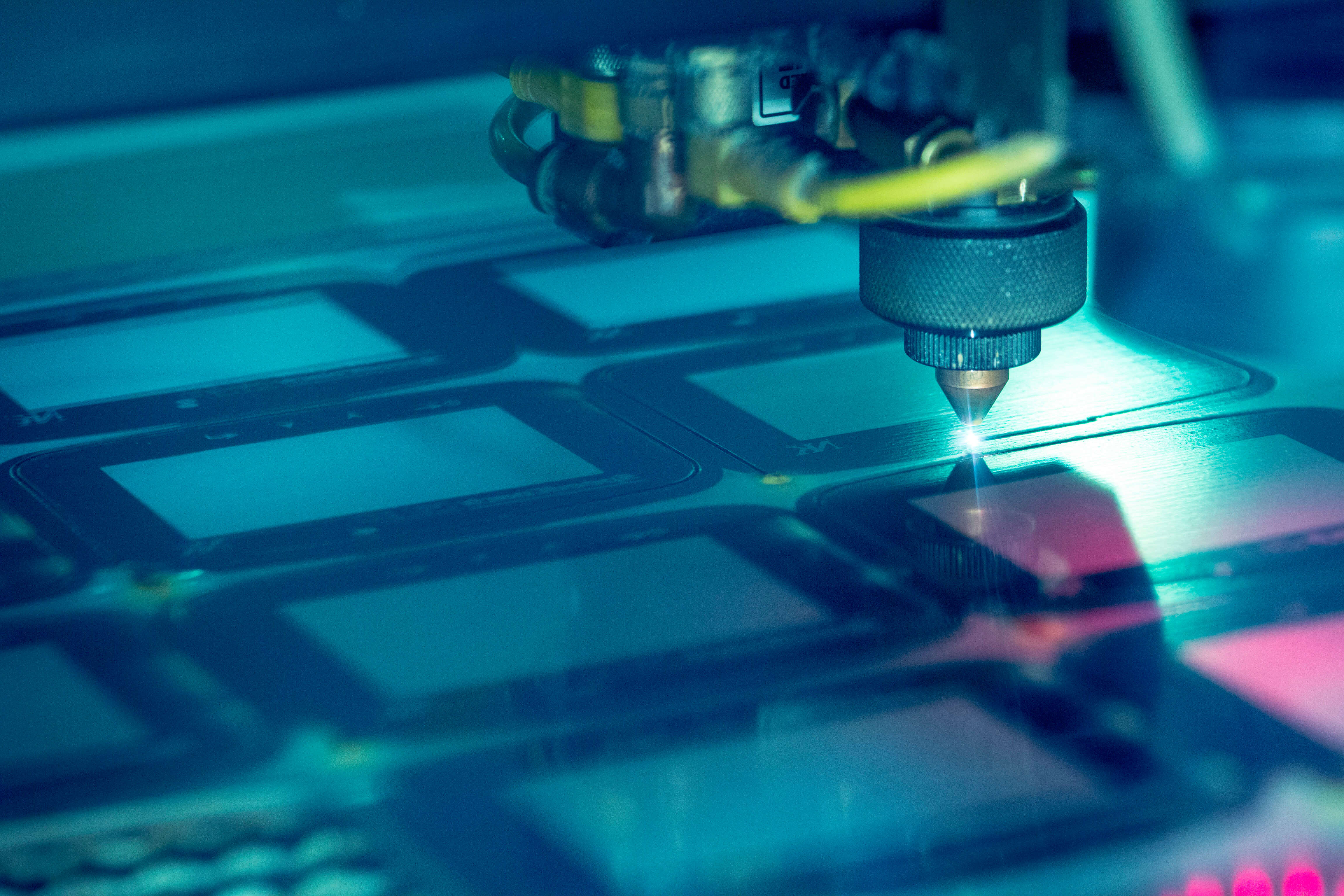

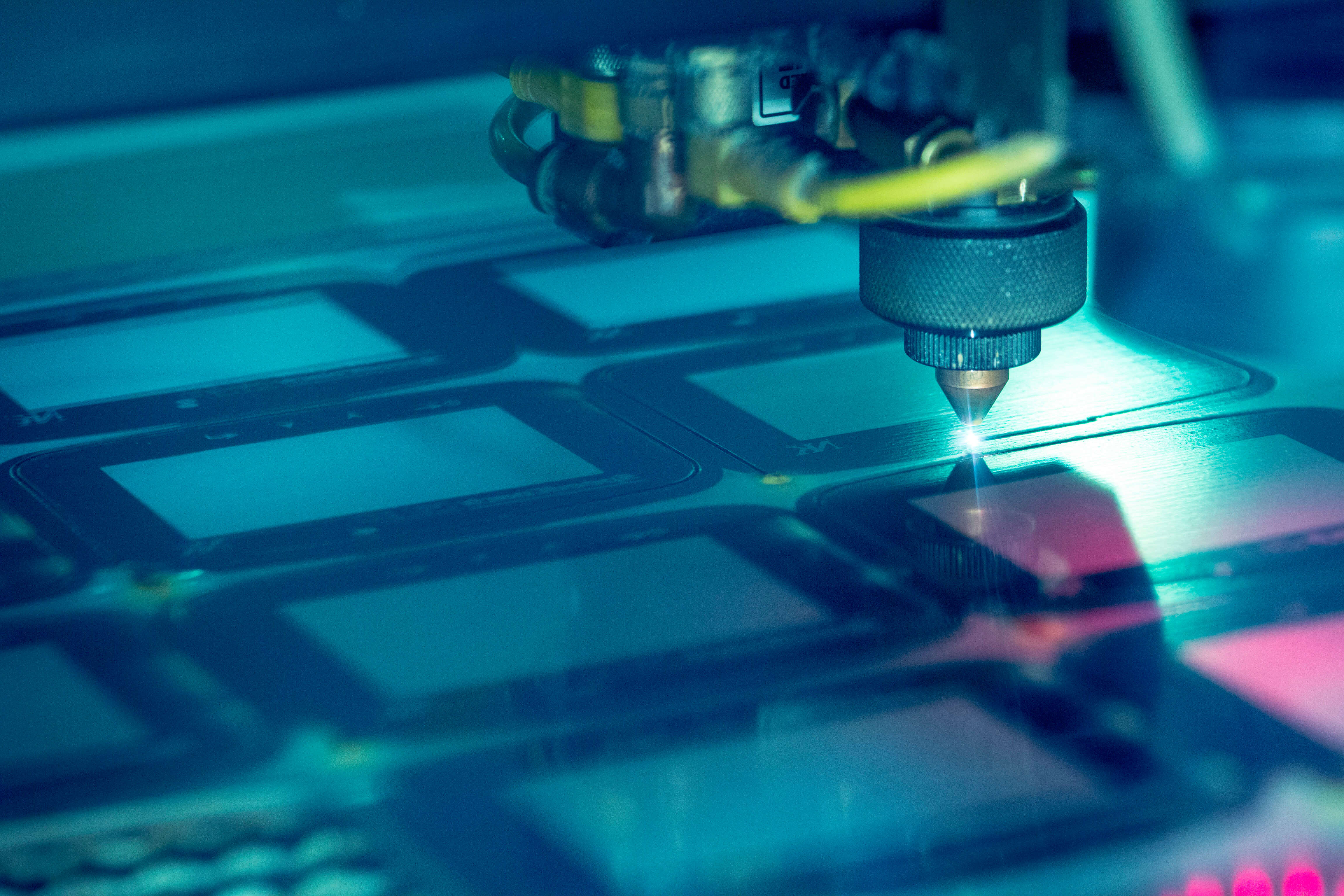

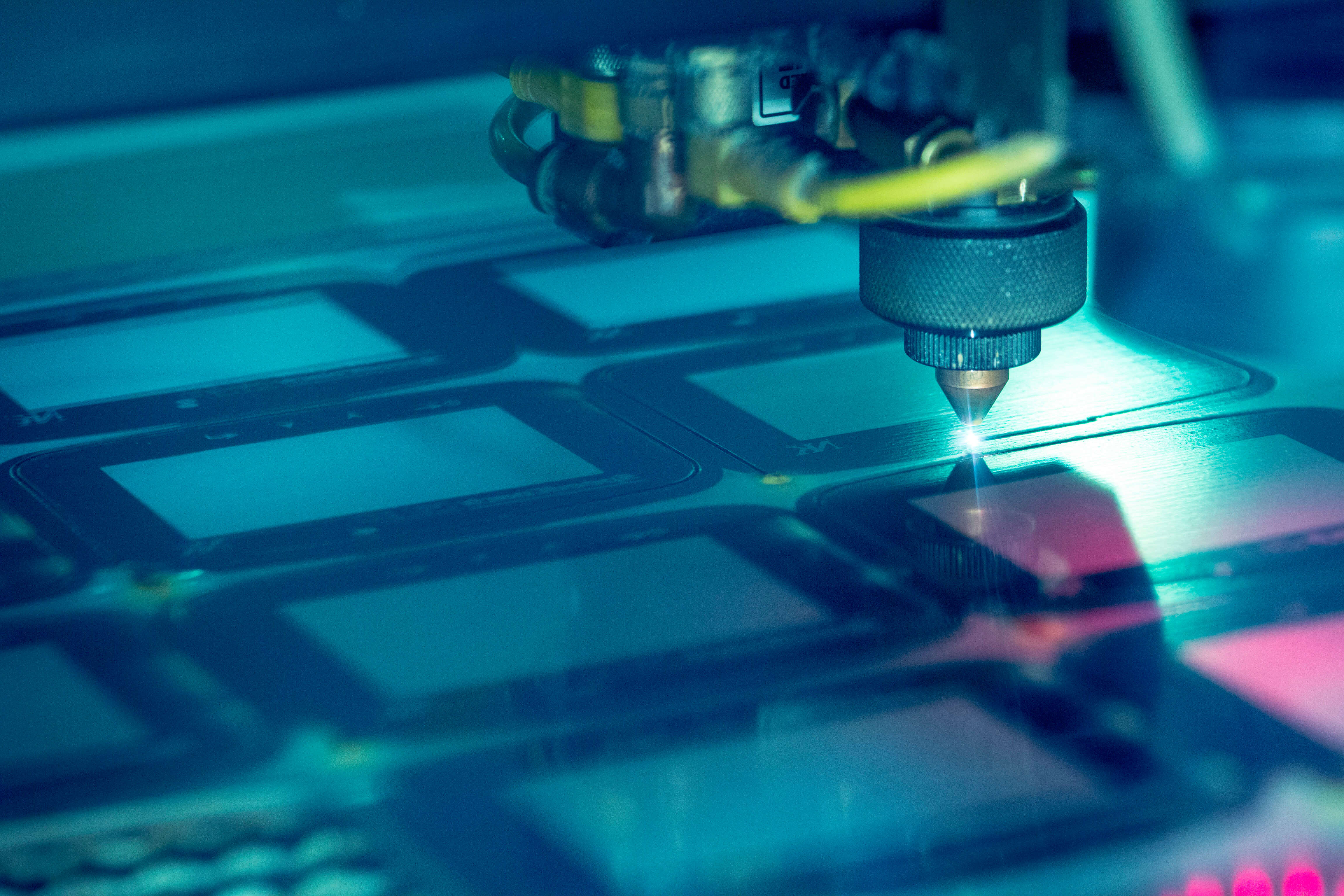

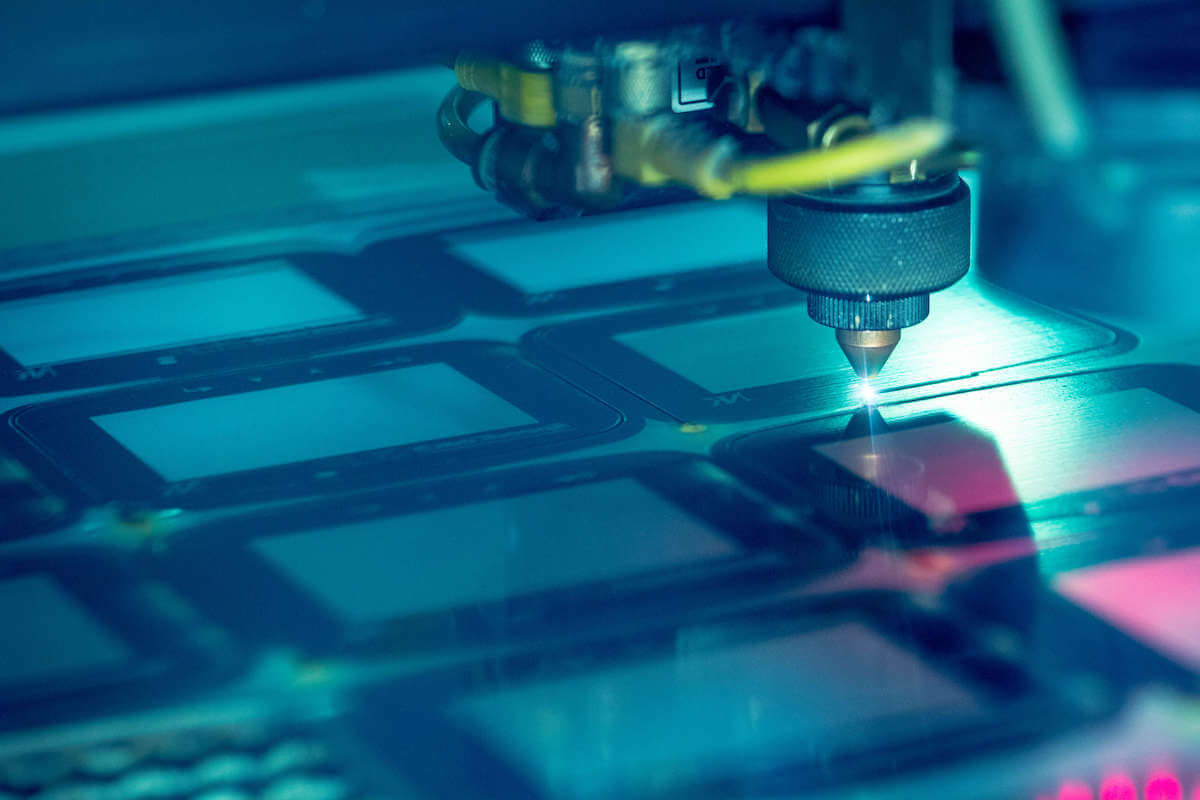

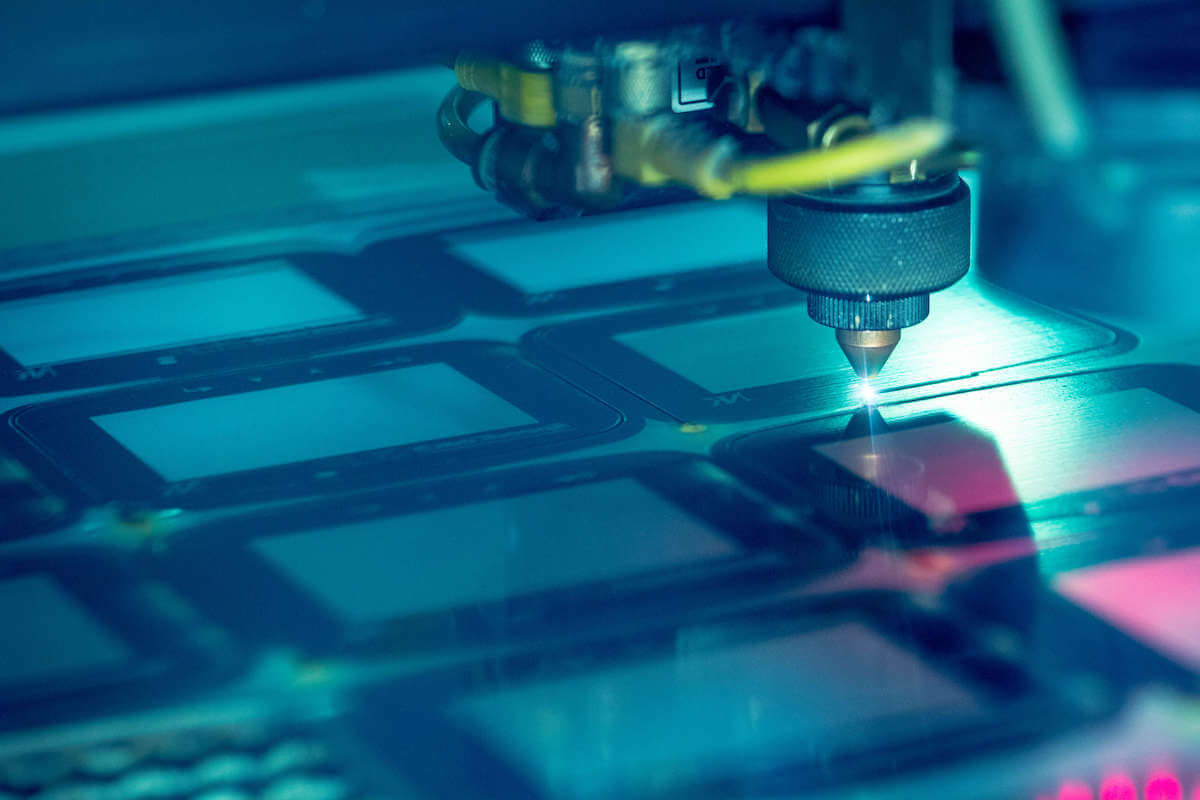

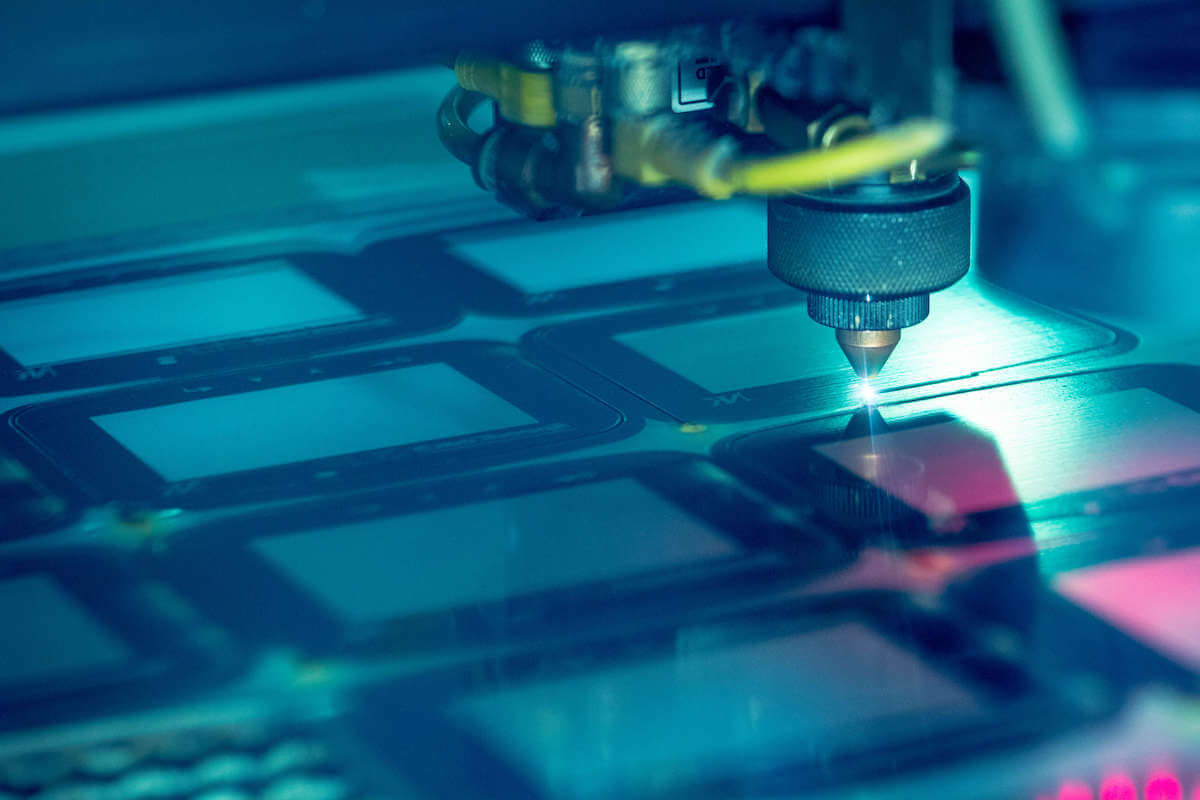

Laser Digital Cutting Systems

Cut types: die cutting, flash cutting, kiss cutting

Our laser-cutting system is precise, cost effective and ideal for every aspect of polycarbonate and acrylic material manufacturing, from prototyping and short-run projects to full production of otherwise hard-tooled programs. Our multiple machines, at our 2 different manufacturing facilities, can cut with extreme precision on polycarbonate materials up to 1MM thick and acrylics as thick at 5MM.

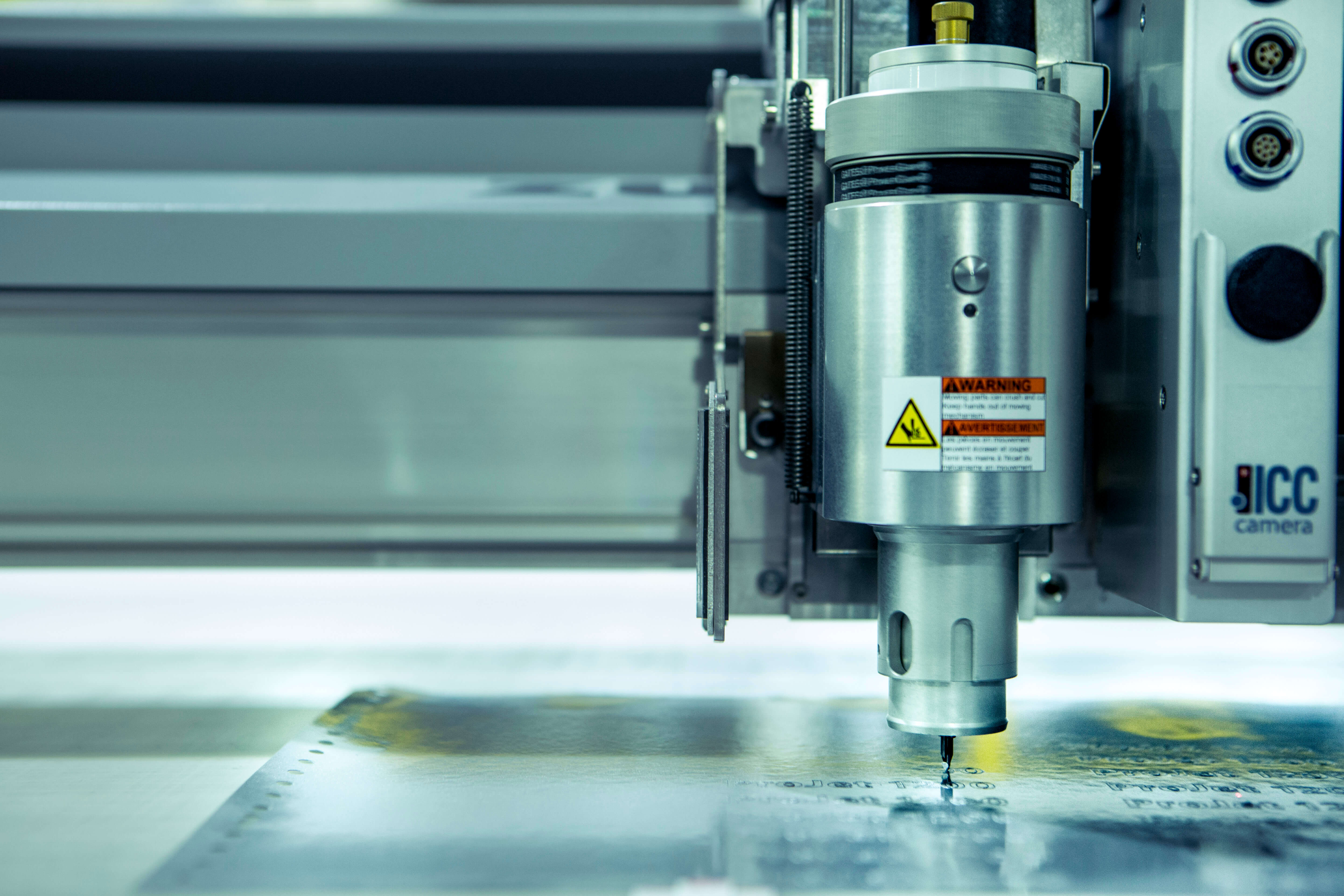

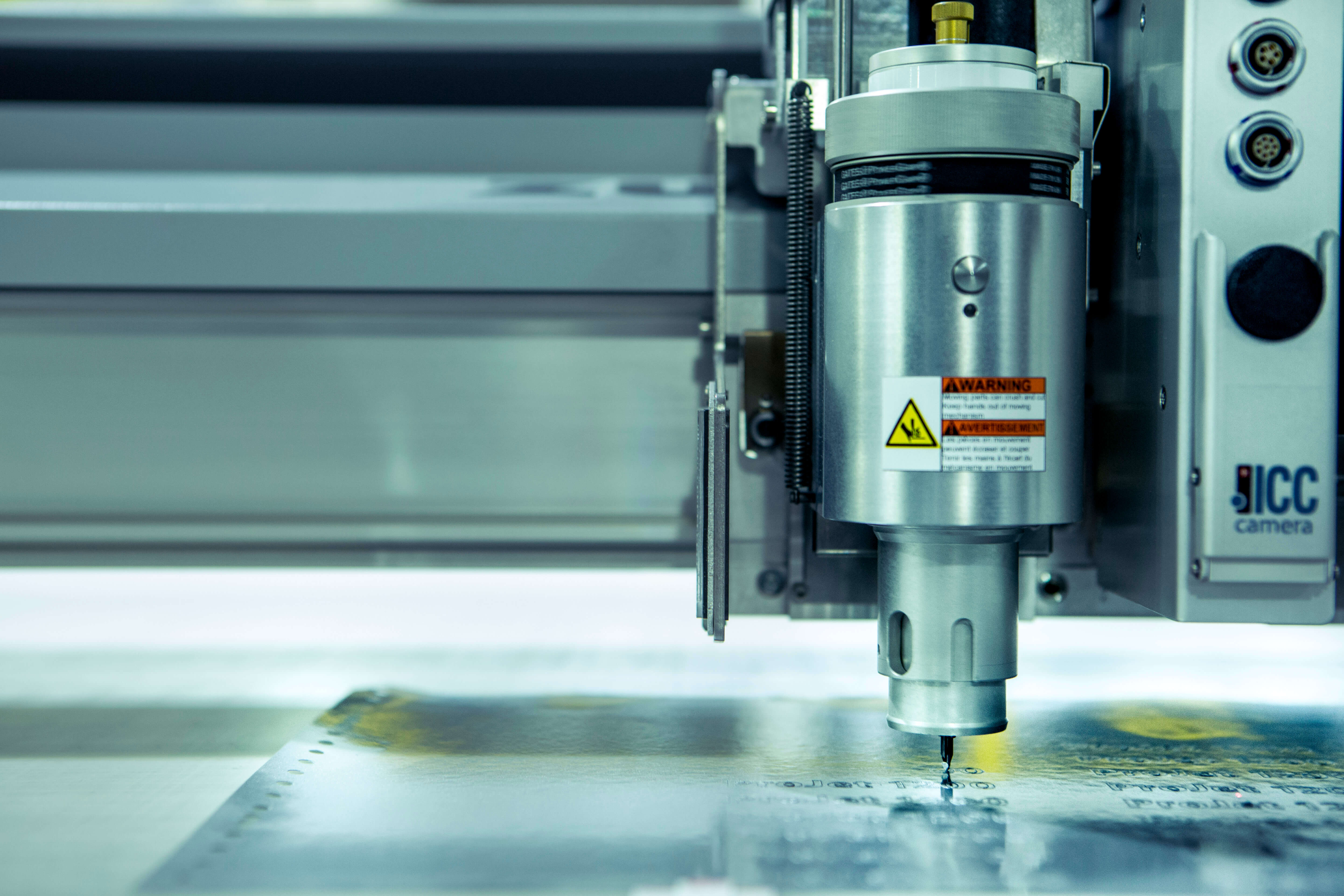

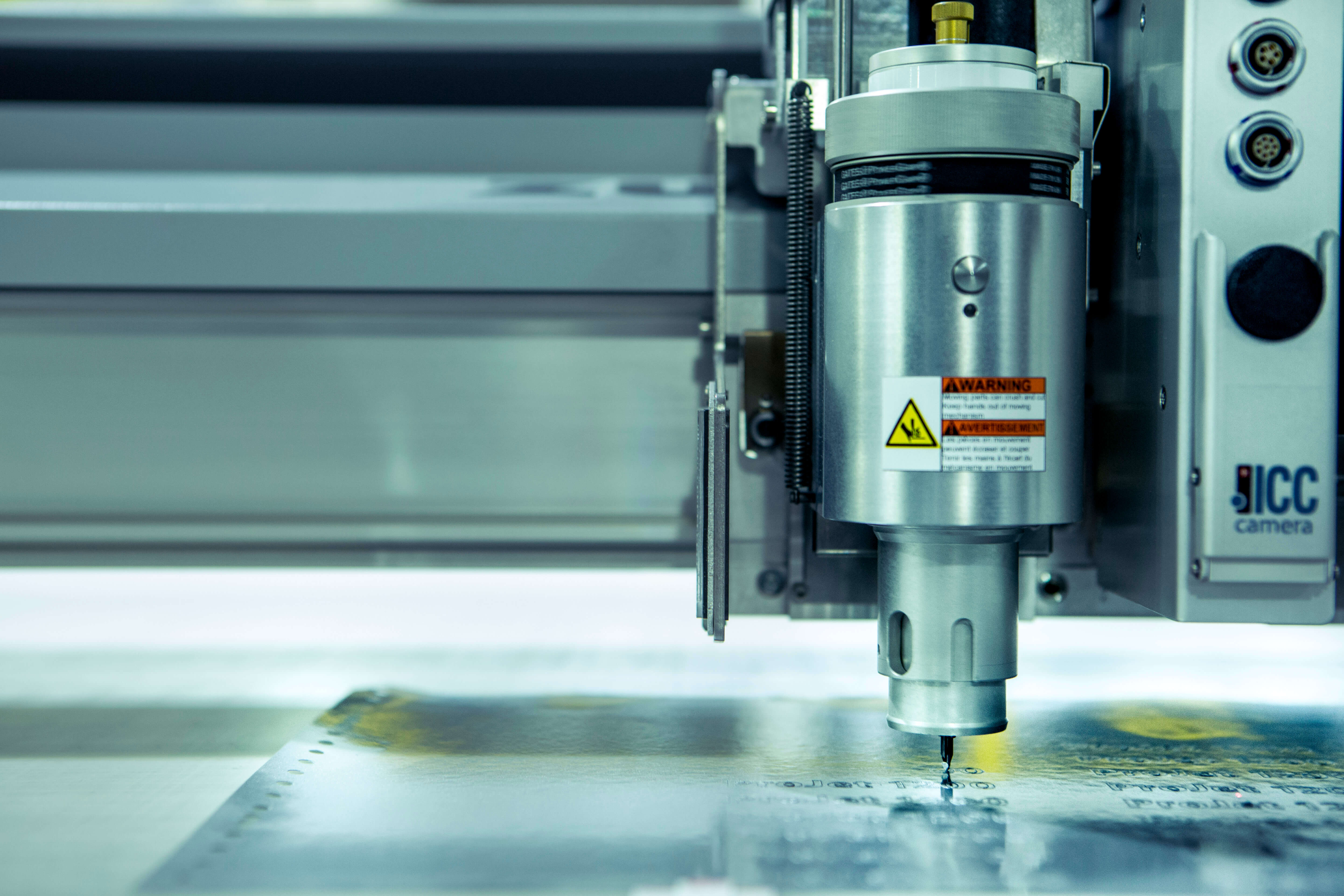

Zund Precision Blade Digital Cutting Systems

Cut types: die cutting, flash cutting, kiss cutting

Our Zund Digital Blade Cutting Systems excel at cutting a variety of materials, particularly in short-run projects. We typically recommend and use this method on kiss cut label jobs where the volume warrants digital cutting (no tooling) and the customer wants several parts delivered on a carrier sheet.

**Both of the above “digital” cutting processes allow us to provide prototypes with an extremely quick response time. If we have your material on hand, we can get samples cut allowing you to prove out form fit and function within just a few days.

Request a Sample Pack of Precision Cut Components

We know that you might want to feel and interact with our work before committing to a project with us, which is why we’ve put together a variety of samples to send to you, free of charge.