Your vision. Our precision.

At JN White®, we make membrane switches, graphic overlays, complex user interface assemblies, precision cut components and custom extreme-environment labels & decals. But it’s how we do it that makes us different: by using precision to manufacture component solutions that answer our customers’ challenges.

As your build-from-blueprint partner, you can count on our rigorous production tolerances and outstanding color control. Our leading-edge technology includes fast, reliable, cost-effective rapid prototyping and is made to your full production-quality specs. Our in-house engineers bring fresh, critical thinking to every project.

Also, JN White’s Quality System is certified as being in conformity with ISO 9001:2015 by Intertek, so you know quality and confidentiality are built into our process. It’s why we’re the preferred partner for brands big and small, and why we’re known for meeting deadlines and exceeding expectations.

JN White Video Tour

At JN White®, we’re always up for a challenge, and that is why we’re equipped with the latest printing technology, manned by trained experts, and backed by some of the most inventive minds in the industry. But it’s our unyielding dedication to quality and confidentiality that has earned us our ITAR certification and our quality system is certified as being in conformity with ISO 9001:2015 by Intertek. So give us your thundering timelines, your impossible quantities, your application quandaries—and we’ll give you precisely what you need.

Durability. Precision. Collaboration.

You Get it All when You Work with Us.

We Can Handle Your Most Demanding Projects

Membrane Switches

We create custom membrane switches for your products, integrating rubber keypads, metal sub-panels, and housings for the most challenging panel assembly applications in the most demanding environments.

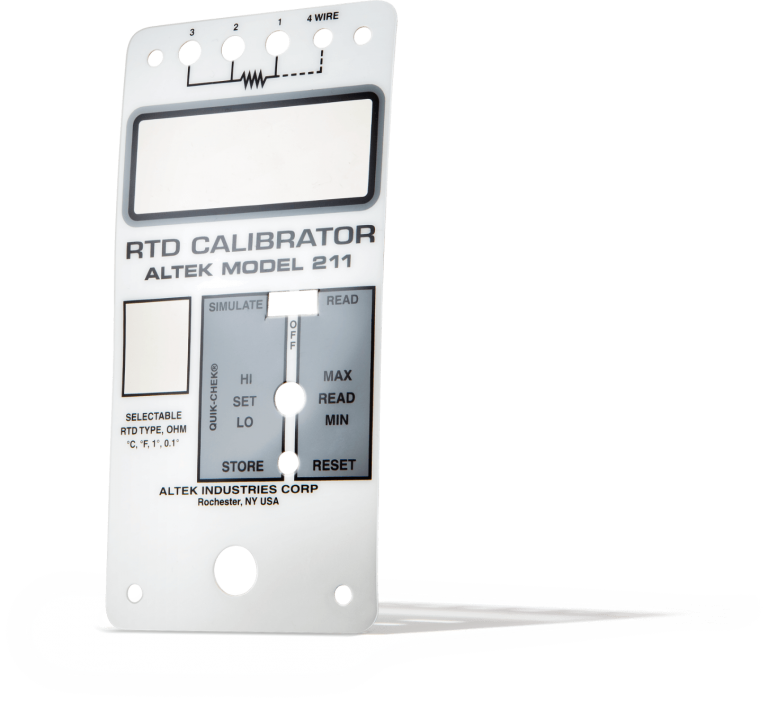

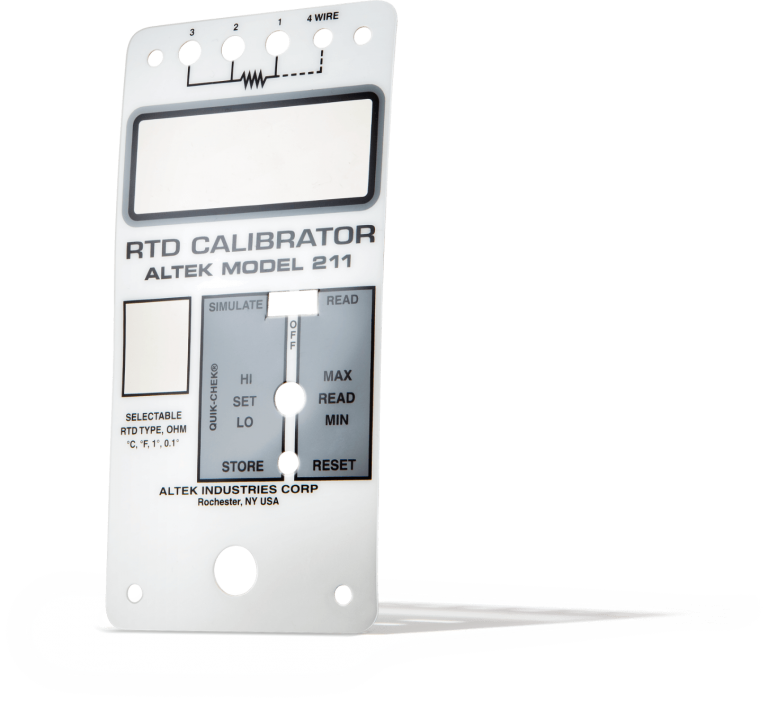

Graphic Overlays

A graphic overlay is the top surface that a user interfaces with when commanding a piece of equipment or control. This is the most customer-facing touch point for many brands, and therefore requires a high degree of care in manufacturing and in effective execution of your design.

Complex User Interfaces

We are experts in design consultation, sourcing, prototyping, production, assembly, and testing of complex user interfaces. Reduce cost and lead time of an interface project using a single source provider.

Backlighting

We work with custom color LEDs, fiber-optic panels, diffusion materials, and opacity solutions including black gasketing materials to provide precise control of lighting panels.

Gaskets

JN White’s® leading-edge cutting process produces perfect cut-to-tape alignment of adhesive gasket assemblies on optical windows and lenses.

Lenses

JN White’s® state-of-the-art cutting process features an optical registration system that enables precision print-to-cut registrations. Our advanced smoke evacuation system assures lenses will be manufactured contaminant free.

ESD Shielding

We engineer to our customer’s specifications and manufacture components to shield the electrical components inside of membrane switches from electrostatic discharge, electromagnetic interference (EMI), and radio frequency interference (RFI).

Custom Labels & Decals

With UL-recognized construction, superior adhesives, exact color-matching science, and product-in-use testing, our labels and decals stand the test of time, wear, and chemical exposure. We deliver using sophisticated printing processes and high-quality materials.

Value-Added Services.

Expertise at every level.

Using Technology to Create Remarkable Things

Manufacturing Engineering

Whether your idea is scribbled on a napkin or provided in an artwork file, JN White will provide best practice consultation and input into your engineering challenges.

Rapid Prototyping

Our 4-step rapid prototyping process can save you time and money, and get your product to market faster. We specialize in prototyping membrane switches, graphic overlays, and labels.

Assembly

We use state-of-the-art techniques to assemble custom projects that incorporate our products and services into the final package—without defects, and always with the highest quality imaginable.

Membrane Switch Testing

Our computerized testing equipment is calibrated annually. It tests dome functioning, LED polarity, and any circuit shorts prior to shipping. We also keep computerized records of all tests for easy reference.

Vendor Managed Inventory

At its core, these VMI programs allow us to support our Customer’s demands for reduced inventory, increased inventory turns and JIT (just in time) inventory management.

60 Years of Solid Reputation

Superior Quality

Fast Turnaround Time

Precision Products

Responsive Customer Service

Rapid Prototyping

Leading-Edge Technology

Team Spotlight

Consult with an expert on your project

We have a team full of experts. Ken Boss is the one of our experts that can answer anything related to user interfaces. He’s been working for us for over 32 years and knows more about membrane switches, graphic overlays, complex user interfaces, and UL labels than anyone we know. Our blog is chock-full with tips from him. Go ahead, have a read. We guarantee you’ll learn something.