Understanding Faraday Cages and Their Importance in Electronic Protection

In an age where electronic devices are at the core of nearly every industry, protecting sensitive equipment from electromagnetic interference (EMI) and radio frequency interference (RFI) is crucial. One of the most effective solutions for shielding electronics from these disruptive forces is a Faraday cage. But what exactly is a Faraday cage, and why is it essential?

What is a Faraday Cage?

A Faraday cage is an enclosure made from conductive materials such as copper, aluminum, or specially designed mesh. It works by redistributing external electromagnetic fields around its exterior, preventing them from penetrating the enclosure’s interior. This principle, discovered by scientist Michael Faraday in 1836, has since been widely applied in various industries to shield electronics from interference.

How Does a Faraday Cage Work?

When an external electric field encounters a Faraday cage, the conductive material redistributes the electrical charges, canceling out the effect of the field inside the enclosure. This prevents the transmission of electromagnetic waves into or out of the protected space. The level of shielding effectiveness depends on factors such as material type, thickness, and enclosure design.

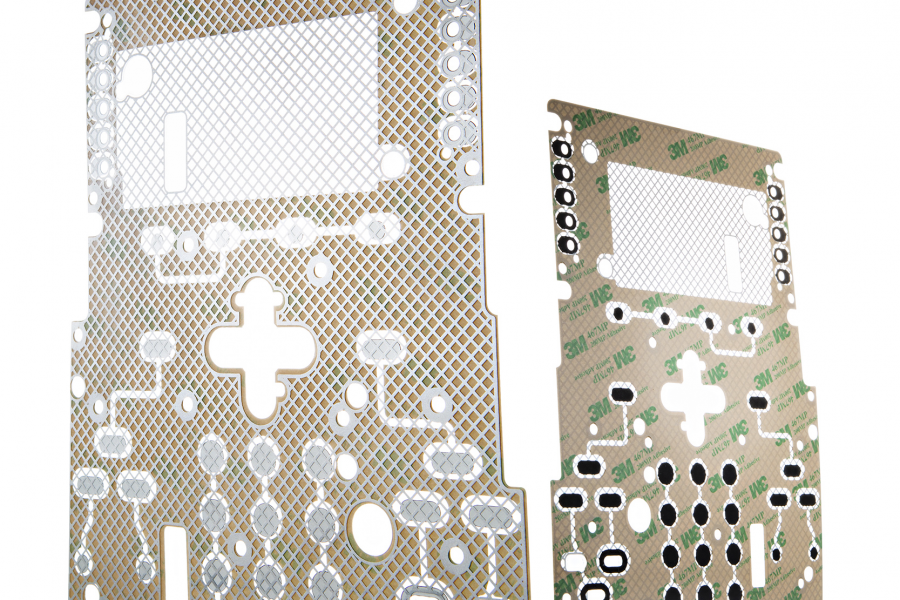

Materials Used in Membrane Switches for Faraday Cages

Membrane switches often incorporate shielding materials to create effective Faraday cages for electronic protection. Some of the key materials used include:

- Copper: A highly conductive metal, copper is widely used in EMI shielding due to its excellent ability to block interference.

- Aluminum: Lightweight and cost-effective, aluminum provides a good balance between conductivity and durability.

- Silver-Inked Shields: Conductive inks containing silver are often printed onto flexible substrates to create lightweight and efficient shielding layers.

- Carbon-Based Coatings: These coatings offer an economical solution for EMI shielding, especially when combined with other materials.

- Nickel and Stainless Steel Mesh: These materials are used in applications requiring durability and corrosion resistance while still providing effective shielding.

Applications of Faraday Cages

Faraday cages are used across multiple industries where EMI and RFI protection are necessary. Some common applications include:

- Medical Equipment: MRI machines and other medical devices require shielding to ensure accurate diagnostics.

- Aerospace & Defense: Protecting communication systems from external interference is critical for operational security.

- Electronics Manufacturing: Ensuring product testing and development occur without EMI disruptions.

- Data Security: Shielding sensitive data from unauthorized access in government and corporate settings.

- Automotive & Industrial: Preventing interference in control systems and electronic components.

Custom Solutions for Your Industry

At JN White, we understand the importance of precision when it comes to electronic shielding. Our expertise in designing and manufacturing custom solutions allows us to integrate Faraday cage principles into membrane switches, graphic overlays, and flexible printed electronics. Whether you need EMI shielding for a medical device or industrial control panel, we have the materials and engineering expertise to deliver reliable protection.

Final Thoughts

A Faraday cage is a fundamental technology for protecting electronic devices from unwanted interference. Whether in medical, aerospace, or industrial applications, having the right shielding solution is crucial to maintaining performance and reliability. If your project requires EMI or RFI protection, contact JN White today to explore customized solutions tailored to your needs.

More from Ken

Biosensors stand at the cutting edge of precision detection technology, integrating biological components with electronic systems to deliver fast and accurate measurements of various analytes. As the need for advanced diagnostic tools and monitoring systems escalates, biosensors are set to…

In today’s rapidly evolving technological environment, the need for innovative and dependable membrane switch prototypes is continuously increasing. As a leading membrane switch manufacturer, JN White excels in crafting custom membrane switch prototypes that not only meet your specific design…

Projected Capacitive (PCAP) touch technology has revolutionized modern touchscreens, providing highly responsive, durable, and intuitive user experiences. From smartphones to industrial control panels, PCAP touchscreens are now the gold standard for applications requiring precision and reliability. At JN White, we…