"JN White has consistently demonstrated a high level of responsiveness and collaborative engagement in the process of rescheduling orders, which has significantly contributed to maintaining excellent customer service"

Bouheng L., Medical Device

"After brainstorming some innovative ideas and doing a few trial runs, JN White was able to do the complete operation at their facility. The results were excellent - higher quality at reduced cost. Love doing business with the friendly and innovative staff at JN White."

Roger W., Building Technology

"It was a very good experience because my contacts were very knowledgeable and they provided the exact material for my decals that I was envisioning. I found them very helpful and will definitely use them again for future projects.

Paula G, Machinery & Equipment Manufacturing

"The quality of your work is second to none. We really appreciate you being a supplier of our critical components."

Roger W., Home Products

"JN White's sales & engineering staff were quite helpful in rounding out cost & engineering details for a quality end product at the right price."

John S., Information Technology

"I highly recommend JN White for any overlay needs. Every order with them has been professional, easy to order from start to end, and the product quality has been outstanding."

Brian C., Power Electronics

"JN White was very accommodating and was able to expedite my order when requested, allowing my production to continue without interruption"

Gary N., Building Technology

"JN White has been exceptional in working with our company in order to develop the look and feel of our new MRI patient worn transmitter. We had originally worked with a prior manufacturer for an earlier version of this product with much less desirable results. JN White delivered a clean professional product at a very reasonable price on time!"

Gary P., Medical

"We had very little information to work with and Jessica James made it nearly effortless on our end to get us exactly what we needed in a timely manner."

Lexi W., Industrial Equipment

"Getting any after-market graphic overlays done always has a certain risk factor in getting it all right. You guys were helpful, patient, & knowledgeable to achieve the best end result. Even pointing out some things that might be [an] oversight or [areas for] improvements. The outcome was perfect."

John S., Technology

"The print task was between the USA and Australia and everything went so smooth. I submitted a drawing, got a return email for me to confirm what I wanted. Even though this was over the Christmas period the print was waiting for me when I got back to work after the holidays. Great job and thanks."

Matt C., Military

"All of the folks there at JN White that I have talked to and dealt with have been very nice and professional."

Vern L., Industrial

"Customer service is wonderful. Receive confirmations and responses in a timely manner. Product has great quality."

Sara H., Medical

"It has been a pleasure working with JN White. We switched suppliers for some of our products to your company and you have given us higher quality. Excellent work!"

Roger W., Education

"I feel confident that JN White will do my order correctly."

Marie P., Government

"I found working with Sara to be a pleasant experience. We were trying to dial in the color to get just the right look on the printed substrate...Sara sent us a sample print sheet that had several variations, up and down, from the colors we specified, which allowed me to pick exactly the color we wanted. The end result product is perfect!"

Don M., Safety

"Our department has used JN White for a number of years for our inspection labels. They always respond very quickly when we contact them to place an order and communication is great with any questions we have. Highly recommend them."

Jim R., Government

"Easy process and great people to work with."

Richard Z., Military

"I'm very satisfied with your service. Always looking forward to bring the best!"

Ramses Z., Medical Devices

"JN White is very responsive to their customers. Product is delivered as expected...and they provide quality products. They have a clear understanding of the obstacles facing US based customers regarding the entire supply chain."

Bob M., Point of Sale

"We always deal with Steve Matacz. He is the best at making sure all details are perfect. Timely communication with any questions we have."

Paul A., Recreational

"Customer response time is one of the best; always prompt and helpful. On-time performance the last 12 months is 100%."

RoseMarie C., Utilities

"Customer service, quality and lead time are great! No complaints."

Sara H., Medical Devices

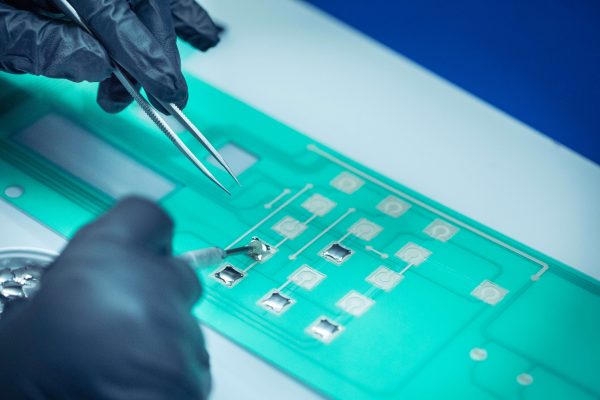

Metal domes come in a large variety of shapes and sizes, with actuation forces between 180 to 700 grams. 340 grams is the most common.

Metal domes come in a large variety of shapes and sizes, with actuation forces between 180 to 700 grams. 340 grams is the most common.