About Tactile Membrane Switches

Advantages

- Excellent Tactile Feedback

- Variety of Shapes and Sizes

- Variety of Actuation Forces

- Long Lifespan (up to 1 million actuations)

Disadvantages

- Higher Costs than Non-Tactile Switches

- More Components to Manage

Graphic Overlay

For tactile switches, the material selected is determined primarily by lifespan requirements.

If you have an application that requires < 50,000 actuations, polycarbonate is a good option; otherwise polyester is the material of choice. Life cycle tests show that polyester can be actuated over 1,000,000 times in a tactile switch without showing signs of wear.

For good tactile feedback in a membrane switch, choose an overlay thickness between .006 and .010. These thickness ranges will offer the durability to meet your requirements, with the sensitivity to provide a quality tactile effect.

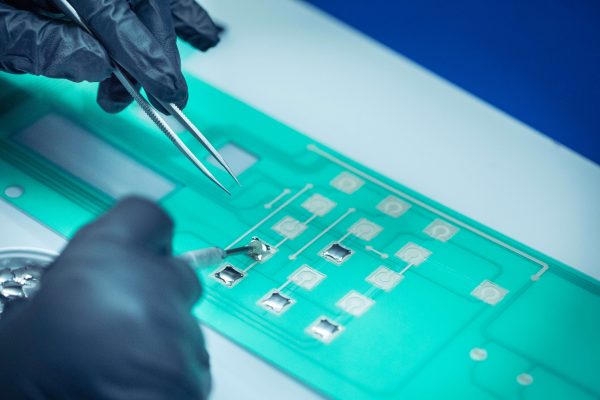

Metal Domes

Metal domes come in a large variety of shapes and sizes, with actuation forces between 180 to 700 grams. 340 grams is the most common.

Metal domes come in a large variety of shapes and sizes, with actuation forces between 180 to 700 grams. 340 grams is the most common.

Metal domes are typically stainless steel, and are nickel-, silver-, or gold-plated. The selected plating depends on the conductivity requirements of the switch, chosen based on electrical resistance. Nickel is the standard, while gold drives down the resistance. Most screen-printed silver circuits are paired with metal plated domes. Gold plating is typically reserved for copper flex or PCBA-based designs.

Another factor that can determine the plating choice is the need to match the material of the underlying circuit. For instance, gold on gold is a common approach to optimize electrical performance.

Polydomes

Softer and quieter than metal domes, plastic polydomes are another option for engineers to create a desired tactile experience.

To make a polydome, a layer of polyester is screen printed with silver “shorting” pad, and then it is thermo-formed into a dome. This also allows you to create multiple buttons across a single panel, and it is a very cost-effective technique for high-volume switches (after the cost of the initial tooling).

Different actuation forces can be achieved by changing the diameter and height of the polydome to meet your requirements.