ENGINEERING THE USER EXPERIENCE

We do more than just design and print membrane switches — we engineer and assemble complete, high-performing user interface systems. Whether you need a simple tactile keypad or a fully integrated, backlit touchscreen assembly, we have the expertise and technology to bring it to life.

The “Top Half” of the Equation

We specialize in the top half of your product — the visible and tactile elements that users interact with every day. This includes everything from the graphic overlay, adhesive stack-up, and circuit layers to integrated components like LEDs, display windows, and domes. Our focus is on delivering an interface that is functional, durable, intuitive, and visually aligned with your product’s design intent.

From Components to Complete Assembly

Our capabilities go far beyond membrane switch printing. We offer full user interface assembly, including:

- Integration of membrane switches, capacitive or resistive touchscreens, display lenses, and backlighting systems

- Installation of custom gaskets, spacers, EMI shielding, and sealing layers

- Electrical connection to PCBs and rigid support layers

- Bonding and final assembly to housings or bezels

- Custom packaging for ready-to-install delivery

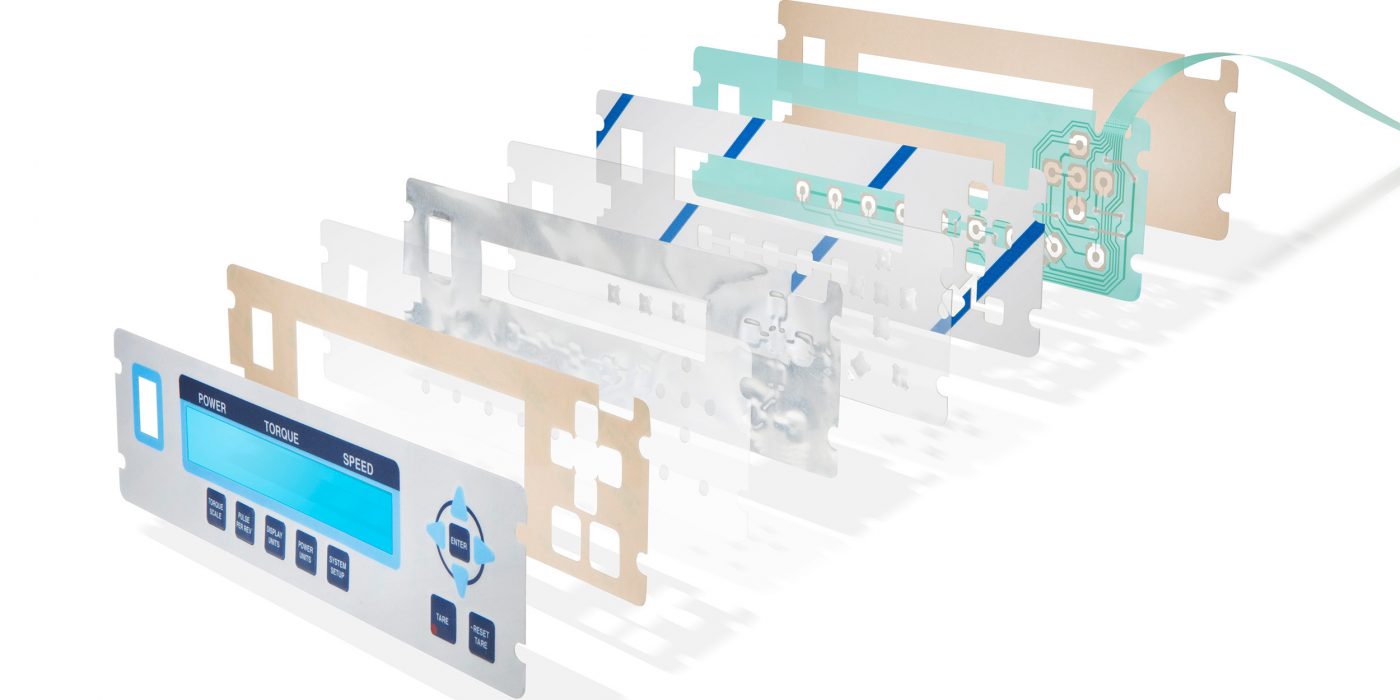

Layers of A Membrane Switch Assemblies

Graphic Overlay Layer

The graphic overlay layer is the topmost layer of the membrane switch assembly and serves as the visual interface. It contains the graphical elements, such as icons, labels, and other visual cues, representing the interactive elements available to the user.

Overlay Adhesive Layer

The overlay adhesive layer is a thin adhesive material applied to the back of the graphic overlay. It securely bonds the graphic overlay to the layers below and ensures its proper alignment and positioning.

Static Shield Layer (optional)

ESD (Electrostatic Discharge) shield layer, is an optional layer that can be included in a membrane switch assembly. It is designed to protect the switch and its internal components from damage caused by electrostatic discharge.

The static shield layer is typically made of a conductive material, such as a metal foil or conductive film, that has low surface resistivity. It acts as a barrier, dissipating any static charges that may build up on the surface of the membrane switch. This layer helps prevent the discharge of static electricity, which can potentially harm sensitive electronic components or disrupt the proper functioning of the switch.

Dome Retainer Layer

The dome retainer layer, also known as the upper circuit layer, is typically made of a rigid material such as polyester or polycarbonate. It provides support and alignment for the dome switches (also known as tactile domes) found in the membrane switch.

Spacer Layer

The spacer layer is a thin material that provides separation between the graphic overlay layer and the lower circuit layers. It ensures that the graphic overlay layer remains in place and prevents accidental actuation of the switches.

Circuit Layer

The circuit layer comprises conductive traces and contacts, typically made of silver conductive ink, etched copper flex or printed circuit boards (PCBa’s). The circuit layer defines the layout and position of the interactive elements (buttons, switches, etc.)

Support Backer Layer (optional)

The backer layer is the bottommost layer of the membrane switch assembly. It provides additional support and protection to the assembly. The backer layer may also include mounting features or adhesive backing for attaching the assembly to a surface.

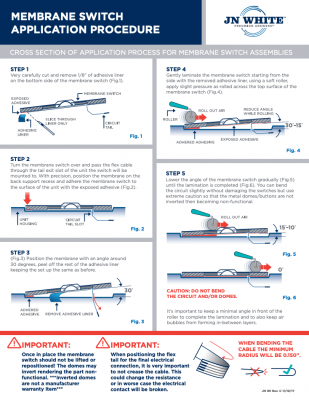

View Membrane Switch Application Procedure as PDF

Manufacturing Processes

Value-Added Services

Expertise and Experience

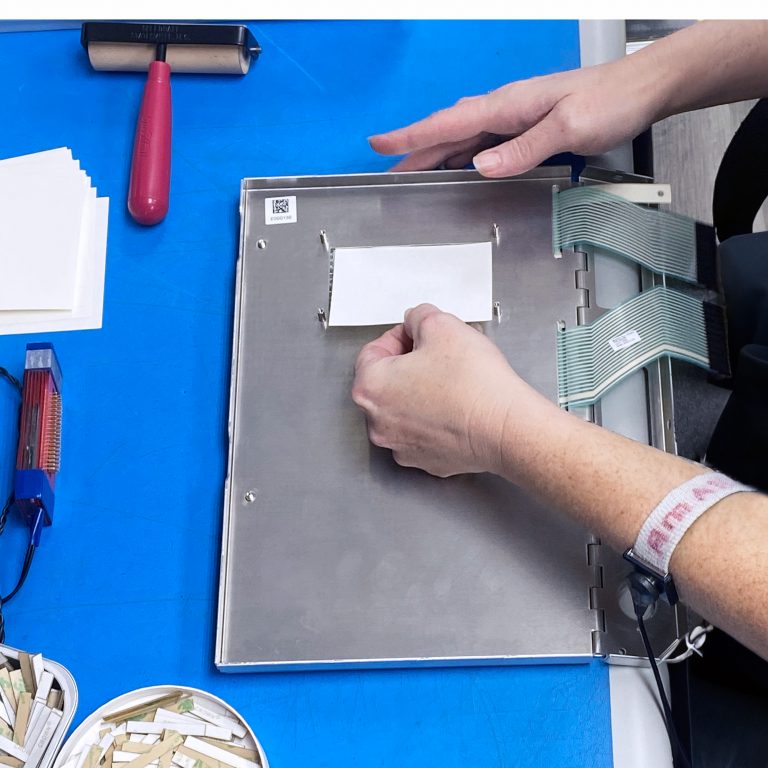

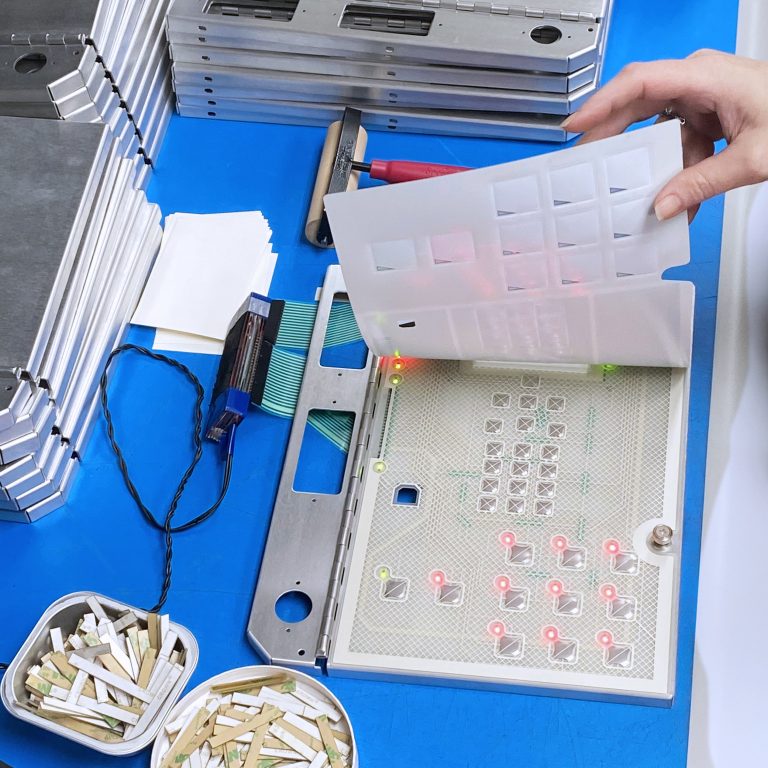

JN White’s professional membrane switch assembly team has specialized knowledge and expertise in the field. They understand the intricacies of membrane switch design, materials, and manufacturing processes. By leveraging their experience, you can ensure that your membrane switch assembly is built to the highest standards and meets your specific requirements.

Scalability

If your business demands a significant quantity of membrane switch assemblies, JN White is well-equipped to meet your scalability requirements. With our robust infrastructure and capacity, we can efficiently manufacture a large volume of assemblies, ensuring timely delivery and meeting your production demands. Our streamlined processes and economies of scale enable us to achieve cost savings, providing you with a cost-effective solution.

Supply Chain Management

At JN White we value the relationships with have with our suppliers and can manage the procurement of materials required for the membrane switch assembly. This saves you the hassle of sourcing individual components and ensures a smooth supply chain. Vendor Managed Inventory>

Design and Customization

Our engineers can optimize your design for manufacturability, ensuring that the assembly process is efficient and cost-effective. Additionally, we can assist with customizations such as incorporating unique graphics, branding elements, or specialized features into the switch assembly.

Warranty and Support

At JN White we provide a 18 month warranty and post-sales support for the membrane switch assemblies we produce. This gives you peace of mind, knowing that you have a reliable partner to address any issues or concerns that may arise after the assembly.

Quality Control

Stringent quality control measures are in place to ensure the reliability and durability of the membrane switch assembly. We conduct thorough testing and inspection at each stage of the assembly process, minimizing the risk of defects or failures. This quality control process helps deliver a high-quality product to you and your customers. 100% of or membrane switches are tested during assembly.

Case Studies

Read about our recent work.