Developing a Unique Complex User Interface From End-To-End

One of the most important aspects of product design is developing the user interface, which ultimately determines how users interact with your product. It’s a critically important consideration that ensures users are able to understand and execute a device’s functionality.

Developing complex user interfaces can be an endeavor that’s even more challenging, combining multiple products and materials together for specific use cases. From backlighting to tactile feel, every new layer that adds complexity to the interface design requires careful and precise engineering to deliver responsive and reliable products.

JN White’s expert engineers help our customers navigate the complex user interface manufacturing process. Whether it’s starting from a blueprint or customer-created design, JN White manages the entire production cycle, translating your interface into a finished product.

Our complex user interface team begins by working with a manufacturer’s designs or technical drawings. Electrical, mechanical, and mechatronic engineering experts thoroughly experienced in manufacturing develop 3D models, reverse engineer parts, and can even provide product packaging.

In the 4-step prototyping phase, JN White’s engineers assemble fully-functional parts and components of complex user interfaces for rigorous testing. The rapid prototyping of graphic overlays, membrane switch designs, and custom labels is our specialty.

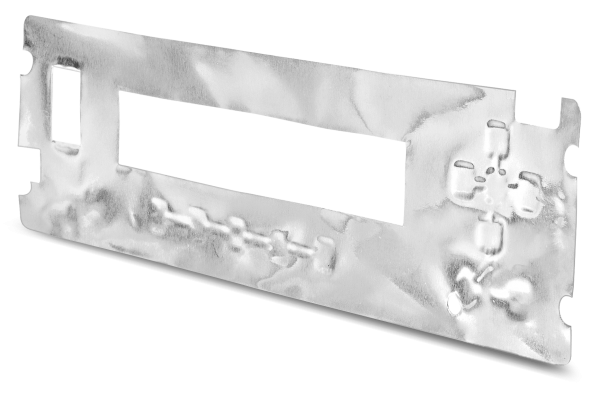

JN White also carries out the custom assembly of complex user interface products, using modern manufacturing techniques to build final products with care and accuracy. From ESD shielding to membrane switch keypads, assembly and sub-panel assembly can be conducted repeatedly to exact specifications, ensuring final products consistently meet industry-specific tolerances. All products manufactured by JN White are tested for 100% functionality using annually calibrated, computerized testing equipment .

As a single production cycle source, JN White also handles product shipment and inventory management. Following lean manufacturing principles, our vendor managed inventory (VMI) program takes advantage of a tightened supply chain to efficiently manufacture products using reduced inventory and just-in-time (JIT) inventory management. With complete visibility and control over our live inventory, customers can enjoy shorter lead times and prompt delivery of any final product.

JN White makes it easy to work with a single team throughout the production cycle of a complex user interface, reducing the cost and lead time of a full project. Since 1960, customers have trusted JN White’s superior outcomes and effortless experience for projects of any size and scale. To streamline your complex user interface manufacturing process, reach out to for a free quote today .

More from Ken

In today’s rapidly evolving technological environment, the need for innovative and dependable membrane switch prototypes is continuously increasing. As a leading membrane switch manufacturer, JN White excels in crafting custom membrane switch prototypes that not only meet your specific design…

Projected Capacitive (PCAP) touch technology has revolutionized modern touchscreens, providing highly responsive, durable, and intuitive user experiences. From smartphones to industrial control panels, PCAP touchscreens are now the gold standard for applications requiring precision and reliability. At JN White, we…

Understanding the Importance of ESD Shielding Electrostatic Discharge (ESD) is a critical concern in electronic device design, particularly for sensitive components like membrane switches. Without proper ESD protection, these switches can suffer from performance issues, reduced lifespan, or even total failure….