Getting Your Product to Market Faster with Rapid Prototyping

Bringing a new product to market doesn’t happen overnight. Refinements that you make to your product’s design throughout the manufacturing processes help ensure that your product is fully-functional and worthwhile. But, each and every tweak that you make to your a product can cost your organization precious time and money in manufacturing, leading to a prolonged product development and manufacturing process that gives your competitors an opportunity to hit the market first.

Prototyping has hundreds of years of history in manufacturing, but recent techniques have changed how manufacturers look at this method in the context of a customer’s product development. Companies like JN White® have embraced modern methods of rapid prototyping to optimize and manufacture our customer’s designs into functional products and reduce time-to-market.

Rapid prototyping allows companies to get products to market as quickly as possible. Using fully-functional parts and components, rapid prototypes allow organizations to thoroughly test product concepts before manufacturing at scale. Rather than relying on a product facsimile, which might not include the same components or design elements of a finished product, rapid prototypes are intended to function as their fully-realized final product.

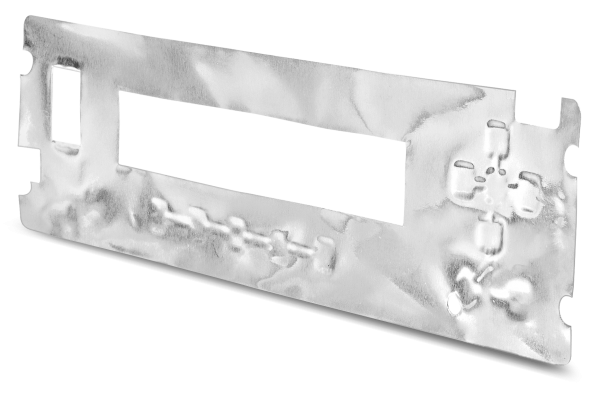

For products with complex user interfaces, rapid prototyping allows organizations to quickly tackle their design challenges and explore manufacturing feasibility. Incorporating membrane switches, graphic overlays, or custom labels, rapid prototyping can help determine whether or not a product concept is repeatedly manufacturable and meets any necessary technical requirements. Eliminating uncertainty about a product’s design and validating key functionality can help make a new product market-ready with speed and accuracy.

Through rapid prototyping, companies can also solicit additional product feedback throughout their design process. Placing a fully-functional prototype in the hands of users, clients, and customers can help refine its design and ensure the product fulfills its intended purpose. Incorporating rapid prototypes into your design process can ultimately help deliver products that are market-ready and free of usability issues discovered late in the manufacturing process.

Since 1960, JN White® has served as a trusted component vendor that solves customers’ complex engineering problems. Using a 4-step rapid prototyping process, JN White® begins by using 3D modeling to visualize our customer’s product design. Products are then digitally printed, cut with high finishing precision, and custom assembled into prototypes for production approval.

From surface material testing to all-inclusive construction samples, our rapid digital printing prototyping services can help meet your product needs throughout every step of the process. Affordable and available in as little as one week, our rapid prototyping can help bring new ideas to life as quickly as possible. Request a quote from JN White to get started on a rapid prototype today.

More from Ken

In today’s rapidly evolving technological environment, the need for innovative and dependable membrane switch prototypes is continuously increasing. As a leading membrane switch manufacturer, JN White excels in crafting custom membrane switch prototypes that not only meet your specific design…

Projected Capacitive (PCAP) touch technology has revolutionized modern touchscreens, providing highly responsive, durable, and intuitive user experiences. From smartphones to industrial control panels, PCAP touchscreens are now the gold standard for applications requiring precision and reliability. At JN White, we…

Understanding the Importance of ESD Shielding Electrostatic Discharge (ESD) is a critical concern in electronic device design, particularly for sensitive components like membrane switches. Without proper ESD protection, these switches can suffer from performance issues, reduced lifespan, or even total failure….