Choosing the Right Features for Your Graphic Overlay

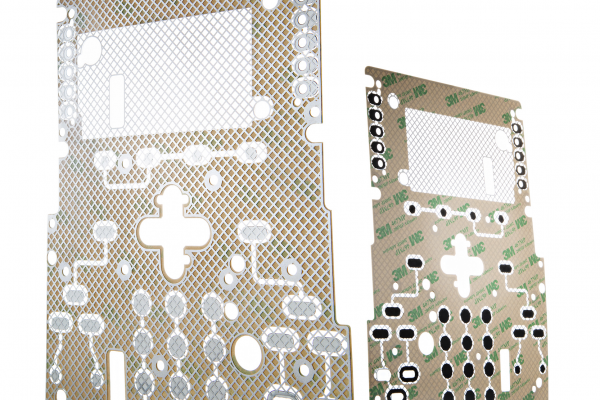

At its most basic, a graphic overlay is the top layer of a user interface panel. But more importantly – and more meaningfully to engineers and brand owners – it is the interface between your customer and the machine. The graphic overlay literally creates the experience users have with your product.

So, what kinds of features should you choose for your product’s graphic overlay? It may sound simple, but I would say this question is best answered by determining what kinds of features you are choosing for your product. As you know, these can check off a variety of boxes.

Here are just a few I’ve had the pleasure of working through!

Withstanding Harsh Conditions

You likely know where your product is going. Are there going to be some obvious environmental concerns? If so, you need to specify the right material for the graphic overlay, since different materials offer different environmental advantages.

For instance, construction equipment requires a more rugged material, like polyester, which is extremely durable and dimensionally stable. Because we print underneath this surface, all the graphics are perfectly protected by the overlay (called subsurface printing).We can even select materials with innate UV protectants to help preserve a “like new” appearance in these outdoor environments.

Indoor environments can be just as challenging. Take medical device applications, for example. These products are subjected to constant use and harsh chemical cleaners, many times a day. They need to withstand these conditions and still operate reliably and dependably. We can help you choose materials that can withstand this kind of wear and tear, and even find options that offer built-in anti-microbial properties to further support the overall product objectives.

Enhancing Usability

What’s the ultimate goal of a user interface? Usability, of course. And the features you choose for your graphic overlay can go a long way toward enhancing the overall usability (and satisfaction with) your product.

By making the graphic overlay easier to feel, operate, and understand, raised buttons and embossed features can dramatically enhance its functionality. The challenge becomes one of trade-offs. While polyester is extremely durable and dimensionally stable, it can also make it difficult to mold and emboss. Conversely, polycarbonate materials are much easier to work with. Unfortunately, this can be at the expense of durability. To address this, we have access to blended materials, which can deliver the best of both worlds.

The design of these dimensional features will once again depend on the use cases of your product. Going back to our outdoor equipment and medical device examples, you can see how there will be differences. Medical devices live in very controlled environments. Clear graphics and lighting choices can give all the visual feedback a user could need. However, outdoor equipment introduces lighting challenges, operators wearing gloves, and a variety of other demands, which can require a more physical feedback component.

Building Your Brand

Don’t underestimate the visual impact of your graphic overlay. Just as you’ve invested in the industrial design of your product to meet specific objectives, so to can your graphic overlay support and reinforce those very same goals.

With these overlays, we can choose ink technologies and materials to deliver specialized textures, finishes, and colors. This allows you to create on-brand graphic treatments, powerful visual differentiation, and market-appropriate design cues. With specialized inks, we can match proprietary brand colors. With the right material, we can deliver the right texture and finish, from matte to high gloss. Add in transparent qualities and vibrant base colors, and you can start to see how may options you really have.

Digital printing gives us even more design freedom, in a very cost-effective way. With these technologies, we can reproduce photographs onto the graphic overlay, allowing you to specify any type of background pattern. Brushed aluminum or carbon fiber patterns for more sophisticated applications. Diamond plate patterns for a more industrial look. As I like to say, if you can think it, we can print it digitally!

As with most components and sub-assemblies, a clear understanding of your product requirements will help drive the right choices for the features of a graphic overlay. But you will always be well-served by understanding beforehand the options you have and the advantages you can gain.

At JN White®, we pride ourselves on working with our customers to engineer a solution that meets their needs, and then helps to exceed them. We love it when you put our expertise to work to deliver a better final product!

Ken Boss is the Vice President of Sales at JN White®, a leading ITAR certified manufacturer with a Quality System certified as being in conformity with ISO 9001:2015 by Intertek. He is an expert in the design and production of graphic overlays, membrane switches, user interfaces, control panels and custom labels. To see additional insights from Ken, please visit www.jnwhiteusa.com/blog.

More from Ken

When people hear the term graphic overlay, they often think of it as just a decorative cover. But in industrial and medical applications, polycarbonate overlays and other engineered materials are much more than a cosmetic detail. They are a critical…

Biosensors stand at the cutting edge of precision detection technology, integrating biological components with electronic systems to deliver fast and accurate measurements of various analytes. As the need for advanced diagnostic tools and monitoring systems escalates, biosensors are set to…

In an age where electronic devices are at the core of nearly every industry, protecting sensitive equipment from electromagnetic interference (EMI) and radio frequency interference (RFI) is crucial. One of the most effective solutions for shielding electronics from these disruptive…