Beyond the Surface: How Industrial Overlays Drive Smarter Interfaces

When people hear the term graphic overlay, they often think of it as just a decorative cover. But in industrial and medical applications, polycarbonate overlays and other engineered materials are much more than a cosmetic detail. They are a critical component of the human-machine interface—bringing together protection, usability, and branding into one seamless layer.

As experienced graphic overlay manufacturers, JN White® understands that overlays aren’t just the “top layer” of a device. They’re engineered solutions designed to improve performance, extend product life, and create a better user experience.

Industrial Overlays as a Functional Component

In demanding environments, industrial overlays do far more than display graphics. They serve as:

- Protective barriers – sealing out dust, fluids, and chemicals to safeguard sensitive electronics.

- Tactile guides – providing raised buttons, embossing, or textures that make controls easier to find and use.

- Visual communicators – leveraging high-contrast colors, symbols, and selective backlighting to convey information instantly.

By integrating with circuit layers, touchscreens, and lighting elements, a polycarbonate overlay becomes a key part of the entire system—not just a finishing touch.

Smart Features in Modern Graphic Overlays

Today’s industrial overlays are built with advanced features that align with modern device requirements:

- Capacitive-touch compatibility for sleek, glass-like functionality without sacrificing durability.

- Integrated backlighting that highlights critical controls and improves usability in low-light conditions.

- Specialty coatings such as anti-glare, scratch resistance, or antimicrobial finishes.

- Custom textures and finishes that enhance both usability and brand differentiation.

These engineered options ensure that overlays deliver value beyond aesthetics—they directly improve usability and product reliability.

Key Considerations for Engineers and Designers

When specifying a polycarbonate overlay or polyester option, some important design questions include:

- Will operators be wearing gloves that require raised, tactile features?

- Will the device face outdoor UV exposure, chemical cleaners, or extreme temperatures?

- Are there regulatory or branding requirements that dictate materials, finishes, or ink systems?

- What is the expected product lifecycle, and how must the overlay perform over years of heavy use?

These details ensure your graphic overlay is more than a protective cover—it becomes an asset to the entire device.

Looking Ahead: The Future of Industrial Overlays

As devices grow smarter, so will overlays. The industry is moving toward:

- Hybrid designs that combine tactile keys with touchscreen and display technologies.

- Flexible manufacturing through digital printing, allowing for lower-volume runs with faster turnaround and on-demand customization.

This evolution means overlays will continue to play a central role in how users interact with technology.

Why Work with Graphic Overlay Manufacturers Like JN White

Choosing the right manufacturing partner makes all the difference. At JN White, we combine deep expertise in materials like polycarbonate and polyester with precision printing and assembly capabilities. Every industrial overlay we produce is built to withstand its environment, enhance usability, and reinforce your brand.

When you work with an experienced manufacturer, you’re not just getting a top layer—you’re getting a critical system component engineered for performance and longevity.

Ready to take your overlay design beyond the surface? Contact JN White to discuss your next project and see how a custom solution can elevate your product.

More from Ken

Biosensors stand at the cutting edge of precision detection technology, integrating biological components with electronic systems to deliver fast and accurate measurements of various analytes. As the need for advanced diagnostic tools and monitoring systems escalates, biosensors are set to…

Projected Capacitive (PCAP) touch technology has revolutionized modern touchscreens, providing highly responsive, durable, and intuitive user experiences. From smartphones to industrial control panels, PCAP touchscreens are now the gold standard for applications requiring precision and reliability. At JN White, we…

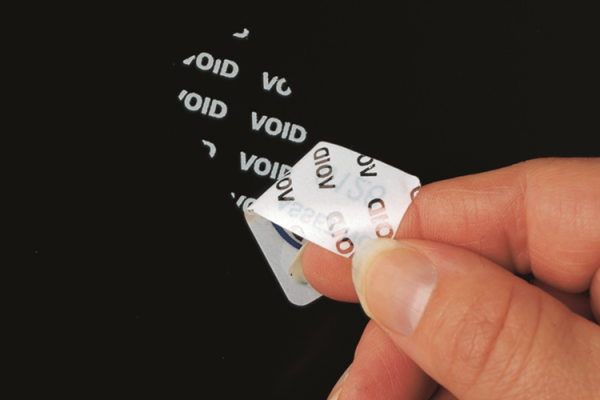

Unveiling Destructible Labels: Exploring Types, Materials, and Their Purpose In the world of labeling, there exists a category of products designed to serve a unique purpose – destructible labels. These labels, as the name suggests, are intentionally crafted to be…