Layer by Layer: How 3D Printing Is Powering the Next Phase of Value-Added Assembly at JN White

Manufacturing is evolving—and so are we.

As JN White continues to expand our value-added assembly services, we’ve taken an important step forward: investing in additive manufacturing technology with the addition of a new in-house 3D printer.

This isn’t just about adding new equipment. It’s about unlocking new possibilities for precision, speed, customization, and customer confidence.

Why 3D Printing? Because Manufacturing Isn’t Static.

In today’s environment, designs change. Tolerances tighten. Timelines shrink.

Traditional manufacturing methods like machining or injection molding are incredibly effective—but they often require higher tooling costs, longer setup times, and less flexibility for frequent design revisions.

Additive manufacturing changes that.

By building parts layer by layer, 3D printing allows us to:

-

- Rapidly prototype new ideas

- Adjust designs quickly

- Reduce tooling and setup costs

- Minimize material waste

- Create complex geometries with ease

For a company increasingly involved in intricate assemblies, that flexibility is a game-changer.

Solving a Real Problem: Housing Fit Verification

Here’s a perfect example.

We recently printed a component that mimics a customer’s housing. Why? So we can assemble our parts and verify proper fit—without requiring the customer to ship us their costly production housing.

That means:

- No risk to their finished components

- No production delays

- No unnecessary shipping

- No guesswork

We validate alignment, tolerances, and final fit internally—before the product ever leaves our facility.

It’s proactive quality control.

Precision Where It Counts

As our value-added assembly services have grown, our need for more accurate fixturing has grown with it.

As our assemblies have become more advanced, we saw an opportunity to enhance our fixturing methods to match that increased complexity. That’s what led us to acquire this 3D additive printer.

Now, we produce:

- Custom assembly jigs

- Fixtures tailored to specific projects

- Alignment guides

- Validation tools

All in-house. All on demand.

This gives us complete control over our assembly environment—and allows us to adapt quickly as projects evolve.

Flexible Manufacturing for a Competitive Edge

Additive manufacturing isn’t just about speed—it’s about agility.

In modern manufacturing, customization is becoming more important than mass production alone. Being able to revise a design, modify a tolerance, or adjust a feature without investing in expensive new tooling makes companies more nimble and competitive.

By bringing 3D printing in-house, JN White can:

- Respond faster to engineering changes

- Support short-run or highly customized projects

- Strengthen collaboration with customers

- Reduce overall project risk

We’re not waiting on external tooling. We’re building solutions in real time.

When Even More Precision Is Needed

While 3D printing offers incredible flexibility, certain applications demand even tighter tolerances. To complement our additive capabilities, we’ve also invested in a CNC router to create ultra-precise fixtures and customer components when required.

The result? We now have the ability to match the right technology to the right application—ensuring optimal performance every time.

More on that expansion soon.

Building the Future—Literally

The addition of additive manufacturing marks another step forward in JN White’s commitment to innovation.

It allows us to:

- Strengthen our value-added assembly services

- Improve quality validation processes

- Reduce customer burden

- Protect high-value components

- Accelerate production timelines

Every layer printed represents more than just material—it represents greater control, better precision, and smarter manufacturing.

At JN White, we’re not just assembling parts.

We’re building better processes—layer by layer.

More from Ken

Why MD&M West Matters—And Why JN White Will Be There MD&M West isn’t just another trade show—it’s where advanced manufacturing sets the tone for the year ahead. Bringing together more than 1,700 medical, critical, and advanced manufacturing suppliers, MD&M West…

NIST Special Publication (SP) 800-171 is the cybersecurity standard that the Department of Defense (DoD) relies on to protect Controlled Unclassified Information (CUI) in non-federal systems. It defines 110 security requirements across 14 control families, along with 320+ assessment objectives that organizations must meet…

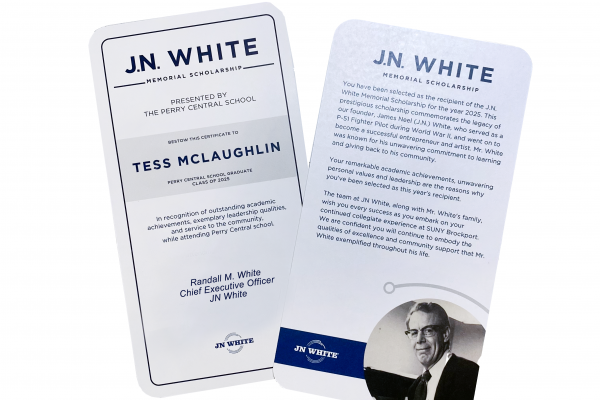

The JN White Memorial Scholarship Committee is proud to announce that Tess McLaughlin has been selected as the 2025 recipient of the JN White Memorial Scholarship. Tess embodies the spirit of leadership, academic excellence, and community service that this scholarship…