Top 6 Adhesive Materials

In this blog, we’ll take a deep dive into the top 6 common adhesives used by JN White, examining their unique properties and applications used in our manufacturing processes. With over 50 years of experience, JN White has become a leader in adhesive technology, working with a wide range of materials including polycarbonates, polyester, vinyl, and more.

We’ll explore the unique properties and applications of some of the most commonly used adhesives in our manufacturing processes, and explain why they are ideal for creating high-quality, durable products that meet the needs of a wide range of industries.

At JN White, we understand that each adhesive has its own set of advantages and disadvantages, which is why we carefully select the best adhesive for each project based on its specific requirements. From high-strength adhesives for automotive applications to medical-grade adhesives for sensitive medical devices, we have the expertise and experience to deliver a high-quality product that meets your exact bonding specifications.

Whether you’re looking for a custom adhesive solution for an industrial control panel or a membrane switch for a medical application, JN White has you covered.

Join us as we explore the top 6 common adhesives used by JN White, and learn how our innovative manufacturing processes and cutting-edge technology can help bring your project to life.

- 3M Adhesives

- 3M 467 (.002”) – For high surface energy substrates with a smooth surface.

- 3M 468 MP (.005”) – For high surface energy substrates with a textured surface.

- 3M 300 LSE (.002”)- For low surface energy substrates with a smooth surface.

- 3M 300 LSE (.0035”) – For low surface energy substrates with a textured surface.

Examples of High Surface Energy Metals:

Aluminum

Examples of High Surface Energy Plastics:

Polyimide

Nylon

Polyester

Polyurethane

Polycarbonate

ABS

Examples of Low Surface Energy Plastics:

Polystyrene

Polyethylene

Polypropylene

Powder Coatings

3M adhesives are a range of high-quality, industrial-strength adhesives that are widely used in a variety of applications due to their excellent bonding strength and durability. These adhesives are produced by the 3M company, a global leader in adhesive technology.

3M adhesives are available in a wide range of formulations, including pressure-sensitive adhesives, structural adhesives, and instant adhesives. These adhesives are designed to bond to a variety of surfaces, including metal, plastics, rubber, and wood, and can be used in various applications such as automotive assembly, electronics manufacturing, and construction.

One of the key benefits of 3M adhesives is their ability to provide strong, long-lasting bonds, even in harsh environmental conditions such as extreme temperatures, humidity, and exposure to chemicals. Many 3M adhesives also offer excellent resistance to UV radiation and weathering, making them suitable for use in outdoor applications.

3M adhesives are also known for their ease of use, as they can be applied quickly. Additionally, 3M offers a range of adhesive tapes and films that can be used to bond surfaces without the need for additional equipment or tools.

Overall, 3M adhesives are a reliable and effective choice for bonding applications, offering superior strength, durability, and ease of use in a variety of industrial and commercial settings.

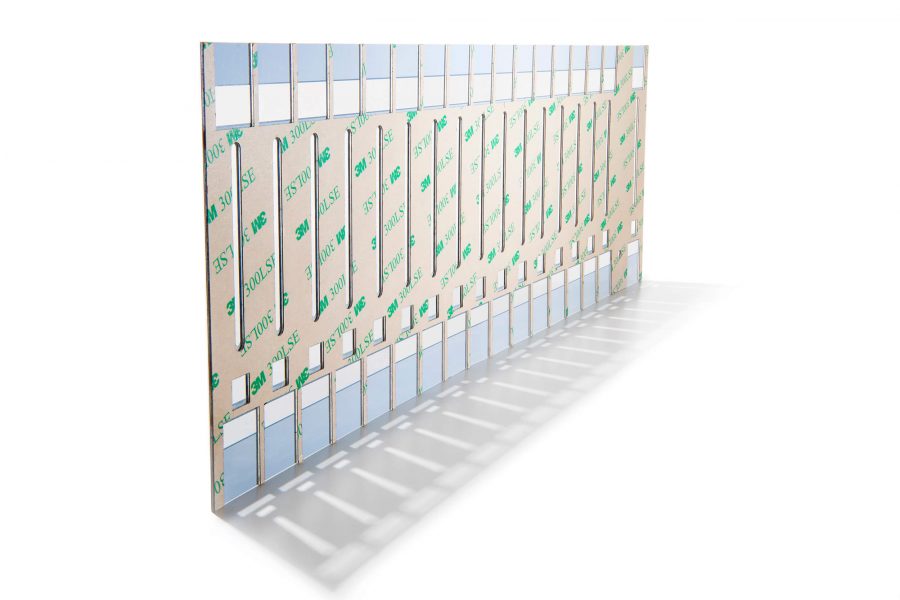

- 3M VHB Tapes

3M VHB (Very High Bond) tapes are a type of double-sided adhesive tape that are widely used in various industrial and commercial applications due to their exceptional strength, durability, and versatility.

VHB tapes are made from a specially formulated acrylic foam that provides excellent bonding strength and durability. This foam is coated on both sides with a high-strength adhesive that creates a permanent bond between two surfaces. VHB tapes are designed to bond to a variety of surfaces, including metal, glass, plastic, and painted surfaces, and can be used in a wide range of applications such as signage, automotive assembly, and construction.

One of the key benefits of VHB tapes is their ability to provide a strong, permanent bond, even in extreme conditions such as high temperatures, humidity, and exposure to UV radiation. VHB tapes also offer excellent resistance to solvents, chemicals, and moisture, making them suitable for use in harsh environments. We use VHB for gasketing in many UI (User Interface) assemblies. With a minimum width of .100” we can hermitically seal an electronic device.

VHB tapes are also known for their ease of use, as they can be cut to size, applied quickly and easily, and require no additional equipment or tools for installation. They also offer a clean and aesthetically pleasing appearance as they create a seamless bond between surfaces.

- 467 and 468 Necal Adhesives

467 and 468 Necal Adhesive are double-coated adhesive tapes. Widely used for bonding applications in various industries. Both tapes have a polyester film carrier coated with a high-strength, modified acrylic adhesive on both sides. The 467 and 468 Necal Adhesive tapes differ in their thickness, with 467 being thinner than the 468.

They have equivalents to 3M 467 and 368 that are typically more cost effective. See this link for the Necal product numbers (https://www.necal.com/transfer-tape) The key to their performance and affordability is that they are a solvent based adhesive. 3M’s are acrylic based products.

The 467 Necal Adhesive tape is a thinner, more conformable tape that provides excellent bonding strength to a wide range of substrates. It is often used in electronic device assembly, bonding small parts, and in applications where high shear strength is required.

The 468 Necal Adhesive tape, on the other hand, is a thicker tape that provides an extra layer of bonding strength, making it ideal for bonding to rough or uneven surfaces. It is often used in automotive assembly, sign manufacturing, and bonding materials with differing coefficients of expansion.

Both tapes offer excellent resistance to high temperatures, UV radiation, chemicals, and moisture, making them suitable for use in harsh environments. They also provide a clean and aesthetically pleasing appearance as they create a seamless bond between surfaces.

Both, 467 and 468 Necal Adhesive tapes are reliable and effective choices for bonding applications that require high strength and durability, even in extreme conditions. They are widely used in various industries and are known for their versatility, ease of use, and excellent performance.

To download our entire Adhesive Matrix visit: https://jnwhiteusa.com/jn-white-top-6-common-adhesives-cheat-sheet/

More from Ken

Biosensors stand at the cutting edge of precision detection technology, integrating biological components with electronic systems to deliver fast and accurate measurements of various analytes. As the need for advanced diagnostic tools and monitoring systems escalates, biosensors are set to…

Projected Capacitive (PCAP) touch technology has revolutionized modern touchscreens, providing highly responsive, durable, and intuitive user experiences. From smartphones to industrial control panels, PCAP touchscreens are now the gold standard for applications requiring precision and reliability. At JN White, we…

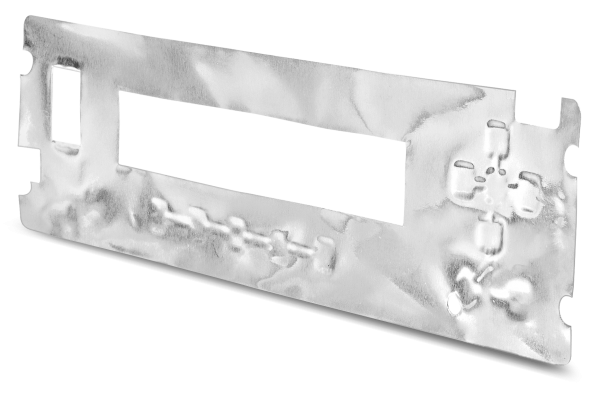

Understanding the Importance of ESD Shielding Electrostatic Discharge (ESD) is a critical concern in electronic device design, particularly for sensitive components like membrane switches. Without proper ESD protection, these switches can suffer from performance issues, reduced lifespan, or even total failure….