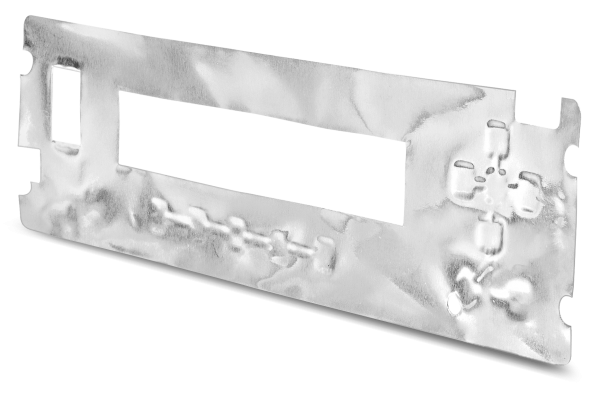

Membrane Switch Prototype

Custom Membrane Switch Prototype

At JN White, we recognize that every project is distinct, which is why we offer a variety of customization options for membrane switch prototypes. From different sizes and shapes to diverse materials and finishes, our prototypes can be tailored to meet your specific needs. Whether you require a simple design or a complex multi-layered switch, our advanced manufacturing processes ensure that your vision becomes a reality.

Custom prototypes offer numerous advantages, particularly in addressing the unique requirements of your users. By closely collaborating with our clients, we create membrane switches that not only align with their functional needs but also enhance the user experience. This focused approach allows for the inclusion of features such as tactile feedback, LED indicators, and custom graphics that resonate with your audience, ensuring that your product stands out in a competitive market.

Furthermore, custom prototypes significantly improve usability and design flexibility. Our skilled designers and engineers work diligently to ensure that each switch prototype is both visually appealing and intuitive to use. This level of customization enables strategic design decisions that can enhance ergonomics and boost user satisfaction. As a top membrane switch manufacturer, JN White USA ensures that your custom membrane switch prototype will not only meet but exceed your expectations, making it the ideal choice for your next project.

Benefits of Rapid Prototyping for Membrane Switches

Rapid prototyping has transformed the development of membrane switches, offering numerous advantages that can significantly enhance the design and production process. One of the most notable benefits is the speed of development and iteration. With advanced rapid prototyping techniques, designers can quickly create functional prototypes, allowing for immediate testing and feedback. This agility enables teams to refine their designs in real-time, ensuring that the final product meets precise specifications and user requirements.

In addition to speed, cost-effectiveness is a critical factor in the rapid prototyping process. By producing prototypes before committing to mass production, companies can identify potential issues and make necessary adjustments without incurring the high costs associated with large-scale manufacturing. This approach not only reduces waste but also ensures that resources are allocated efficiently, resulting in a more streamlined production process.

Real-world applications and case studies further demonstrate the effectiveness of rapid prototyping for membrane switches. Clients in industries such as medical devices and consumer electronics have successfully implemented prototype membrane switches to test user interfaces and improve functionality. These successful iterations have led to products that not only perform better but also resonate more deeply with end users. At JN White, we leverage these benefits to provide our clients with high-quality membrane switch prototypes, ensuring that every product we deliver is optimized for performance and user satisfaction.

Key Components of Membrane Switch Prototypes

Membrane switch prototypes are intricate devices composed of multiple layers, each serving a specific function. Understanding the layers and materials used is crucial for achieving optimal performance. Typically, a membrane switch consists of a top graphic overlay, a spacer layer, and a circuit layer. The graphic overlay not only provides aesthetic appeal but also protects the underlying components. Materials such as polyester or polycarbonate are commonly used for durability and flexibility, ensuring that the switch can withstand repeated use while maintaining its appearance.

Another essential aspect of membrane switch design is tactile feedback, which greatly influences user experience. Tactile switches provide a noticeable response upon activation, enhancing usability and ensuring that users can easily navigate through various functions. At JN White, we prioritize the integration of tactile feedback in our prototypes, allowing for an intuitive interface that meets the needs of diverse applications, from medical devices to consumer electronics.

Moreover, the integration of electronic components plays a significant role in the functionality of membrane switches. Each prototype can be customized with various electronic features such as LEDs or capacitive touch sensors, which can elevate the user experience. Our expertise in seamlessly integrating these components ensures that your membrane switch prototype not only meets aesthetic requirements but also performs reliably under various conditions. By focusing on these key components, JN White delivers membrane switch prototypes that stand out in terms of quality and usability, making them the ideal choice for your next project.

Membrane panels are an integral part of our design process, ensuring that each layer functions harmoniously to create a cohesive and efficient membrane switch prototype. As a leading membrane switch manufacturer, JN White is dedicated to delivering prototypes that excel in every aspect, from design to functionality.

More from Ken

NIST Special Publication (SP) 800-171 is the cybersecurity standard that the Department of Defense (DoD) relies on to protect Controlled Unclassified Information (CUI) in non-federal systems. It defines 110 security requirements across 14 control families, along with 320+ assessment objectives that organizations must meet…

Projected Capacitive (PCAP) touch technology has revolutionized modern touchscreens, providing highly responsive, durable, and intuitive user experiences. From smartphones to industrial control panels, PCAP touchscreens are now the gold standard for applications requiring precision and reliability. At JN White, we…

Understanding the Importance of ESD Shielding Electrostatic Discharge (ESD) is a critical concern in electronic device design, particularly for sensitive components like membrane switches. Without proper ESD protection, these switches can suffer from performance issues, reduced lifespan, or even total failure….