Your Comprehensive Guide to Force Sensors

Welcome to JN White, your premier source for high-quality user interfaces. This article will provide an in-depth exploration of force sensors, their applications, and their numerous benefits. Our objective is to equip you with the vital knowledge you need, whether you’re an engineer, researcher, or simply interested in this technology.

Understanding Force Sensors

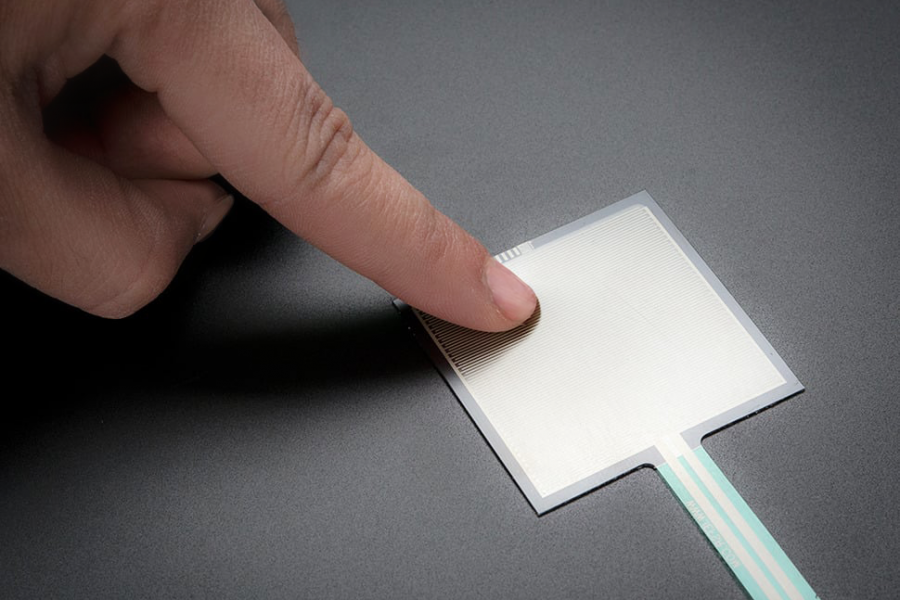

A force-sensitive resistor (FSR), operates based on the principle of changes in electrical resistance when subjected to pressure or force. Here’s how it works:

- Construction: A flexible force sensor typically consists of a flexible substrate material, such as polymer or elastomer, embedded with conductive materials, like carbon or conductive ink. These materials form a conductive path across the sensor.

- Resistance Variation: When pressure or force is applied to the sensor, the flexible substrate deforms, causing the conductive materials to come into closer contact or change their configuration. This deformation alters the resistance along the conductive path.

- Electrical Measurement: The change in resistance is measured using electrical circuitry. Typically, the sensor is connected in a voltage divider circuit, where its resistance varies depending on the force applied. As the resistance changes, the voltage output across the sensor also changes.

- Output Interpretation: The change in voltage output is then interpreted to determine the magnitude of the applied force. This can be done using analog-to-digital converters (ADCs) in microcontrollers or dedicated signal processing circuits.

- Calibration: To ensure accurate force measurement, flexible force sensors often require calibration to establish a relationship between the applied force and the corresponding change in resistance or voltage output.

Flexible force sensors are versatile and find applications in various fields, including medical devices, robotics, automotive, and consumer electronics, where they provide a cost-effective and adaptable solution for measuring force and pressure.

Applications of Force Sensors

Automotive Industry: Force sensors measure the impact force during collisions, which helps in crash testing and ensuring vehicle safety. They also aid in research and testing to guarantee optimal performance and durability.

Medical Field: Force sensors find extensive use in the medical industry for various applications requiring precise force measurement. One notable application is in medical devices designed for rehabilitation and therapy, such as swallow therapy systems for stroke patients. These sensors, engineered with a silver conductive circuit on a poly substrate, accurately measure tongue pressure variations during therapy sessions. Clinicians rely on this data to assess patient progress with unparalleled accuracy, tailoring therapy programs to individual patient needs effectively. Additionally, the sensors’ high sensitivity and reliability make them suitable for other medical devices and human-machine interfaces where precise force measurements are crucial for optimal performance and patient safety. Read the full case study here.

Robotics: Force sensors, transducers, and force sensing resistors enable robots to interact effectively with their environment. They measure and control force in robotic arms for delicate tasks and ensure safe human-robot interactions by detecting excessive force.

The Benefits of Force Sensors

Force sensors, provide several advantages, making them essential in various industries. They offer accurate force measurement, real-time data acquisition, and a compact, versatile design.

Their high sensitivity and precision allow for accurate readings, even for small forces. Real-time data acquisition provides immediate and continuous force data, improving efficiency and productivity. The compact and versatile design of force sensors allows easy integration into existing systems and is suitable for applications with limited space.

At JN White, we specialize in providing high-quality user interfaces, including force sensors, tailored to meet your project needs. Leveraging our expertise in advanced sensor technology and manufacturing, we can collaborate with you to develop customized force sensors and transducers that precisely meet your specifications. Whether you’re in the automotive, medical, robotics, or any other industry, our team is committed to delivering innovative solutions that enhance performance, reliability, and efficiency in your applications. Contact us today to discuss how we can assist you in integrating cutting-edge force sensing technology into your project.

More from Ken

When people hear the term graphic overlay, they often think of it as just a decorative cover. But in industrial and medical applications, polycarbonate overlays and other engineered materials are much more than a cosmetic detail. They are a critical…

Biosensors stand at the cutting edge of precision detection technology, integrating biological components with electronic systems to deliver fast and accurate measurements of various analytes. As the need for advanced diagnostic tools and monitoring systems escalates, biosensors are set to…

In today’s rapidly evolving technological environment, the need for innovative and dependable membrane switch prototypes is continuously increasing. As a leading membrane switch manufacturer, JN White excels in crafting custom membrane switch prototypes that not only meet your specific design…